The forging manipulators by Siegerland-based company DANGO & DIENENTHAL are best given a wide berth. These transport and handling machines can weigh as much as 1,000 tonnes. Not only that—their load, which can weigh up to 350 tonnes, is still hot, and although considered merely “warm” in steel industry terms, these glowing pieces of steel can reach a temperature of up to 1,200 degrees Celsius. Operational safety is therefore imperative. SICK 3D vision gives forging and transport manipulator drivers a better view, particularly of the area at the rear of the machine.

Clear path of forging and transport manipulators with 3D vision

DANGO & DIENENTHAL builds some impressive machines for its metal and steel industry clients. No less impressive is the material these massive transport manipulators carry in their huge jaws: Blocks of red-hot steel, which are being carried to a hydraulic forging press the size of a small church. Given the dimensions involved, maintaining a constant overview of the working environment can be difficult. In comparison, the machine operator looks like a figure from a model village. But the fact remains that despite these incredible dimensions, the shaping and transportation processes undertaken with the manipulator must be performed with precision at all times. The persons at the controls must know exactly what they are doing—and not just when they’re facing the forging press.

Relevant information for drivers

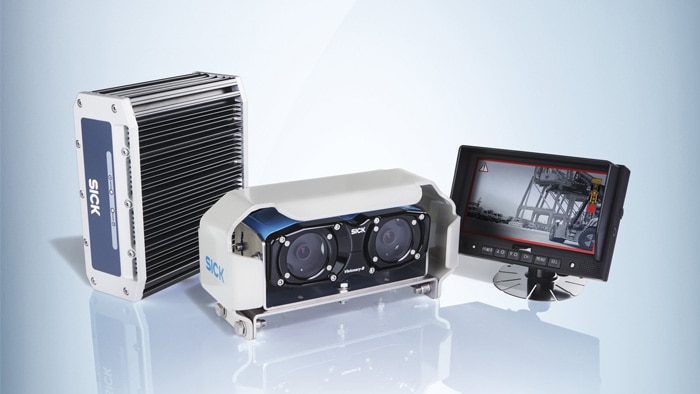

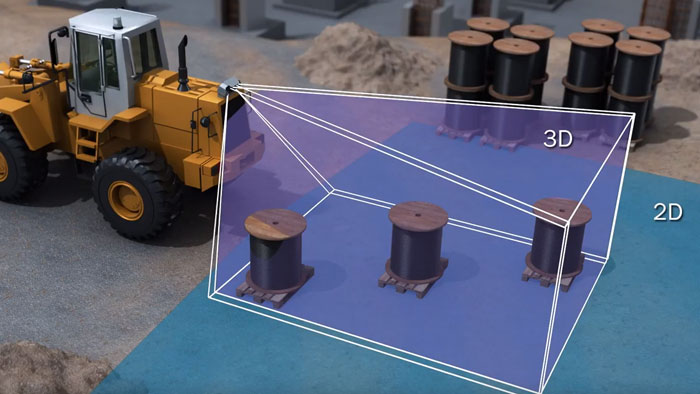

When it comes to reversing assistants, DANGO & DIENENTHAL relies on an active camera system, the Visionary-B 3D vision sensor from SICK. Based on the stereoscopic principle, this system is built on technology that reliably detects structures, objects and obstacles within a three-dimensional space. The system displays every camera image as a live stream in the monitor and the intelligent algorithms ensure that a warning signal is only emitted when relevant objects are detected. These include obstacles such as logistic materials, vehicles or people in the driving area behind the gigantic handling machines. Typical causes of collision include pallets, containers or manned forklift trucks positioned in the driving area. The operator of the SICK Visionary-B driver assistance system can configure which objects trigger an alarm signal and which do not.

SICK’s solution captures the scene with short exposure times, resulting in no time delays. The 3D camera, which is made by the German sensor producer, thus prevents rapid or sudden events from appearing in the image undetected. A further advantage of this 3D technology is the absence of moving components. Traditional stereoscopes require neither rotating mirrors nor a moving object in front of the 3D camera to give a reliable collision warning. “The principle behind Visionary-B is actually similar to human vision since two horizontally positioned objects are integrated by the human brain to construct a three-dimensional image,” says Muhammet Albayrak, one of SICK’s application engineers.

Reliable camera technology

“Our clients were looking for a solution for monitoring the space behind the machine. Previous systems weren’t able to fulfill this requirement to their satisfaction,” reports the development team at DANGO & DIENENTHAL. The technology developed by SICK operates according to this established and rugged three-dimensional process, even in challenging industrial environments such as mines, quarries or steel plants, while ensuring maximum safety. The absence of moving components also makes the solution resistant to knocks and vibrations. For application in DANGO & DIENENTHAL transport manipulators, the rugged, dustproof camera housing is installed in an additional metal box for extra heat protection. Because of the poor visibility at the rear of the machine, the system is operated outside of the general specifications on mounting height and aperture angle. The installation was therefore validated with experts from SICK through running appropriate test routines prior to series deployment.

Early warning system for blind spots

Overall, it must be ensured that the 3D driver assistance system is not negatively impacted by the adverse ambient condition of the forging process. However, reliability should not be reduced to distracting the driver with an audible or visual alarm for any event or irregularity that occurs in the rear image. The focus should instead be on only alerting the driver to the most critical situations. Every false alarm diminishes trust in the system. The commissioner at DANGO & DIENENTHAL says “Time was lost in transportation, which had the knock-on effect of causing delays in the forging process. The manipulator driver can only work at full speed if they can be sure that the route behind them is being reliably monitored. They constantly need to move backwards and forwards to reposition the hot, glowing components. Visionary-B from SICK is therefore a good solution for us.”

Speed is also needed on the trip from the reheating furnace to the forging press. The longer transportation takes, the faster the block of steel cools down. This also applies to unplanned stops or handling faults. In the worst-case scenario, the component must be returned to the furnace so it can be brought back to its target temperature (approximately 1,200 degrees Celsius). Taken together, delays in the logistics chain for these challenging components have a direct impact on production times and result in a tangible reduction in energy efficiency. The extra costs for labor and energy therefore eat into valuable business income. This is why DANGO & DIENENTHAL has continued to build on its reputation as a global market leader and driver of innovation—and has chosen to invest in a new reverse monitoring system for its impressive machines.

I want to stay up to date and regularly be informed about new articles!