Quality control is essential for companies to ensure that the products they bring to market meet industry standards and produce the desired result. It is often a demanding process, however, due in part to the ever faster production rhythm and the complexity of identifying defects. Intelligent quality control solutions automate this process and ensure a thorough and precise inspection – as demonstrated by the Italian specialist Tekna Automazione e Controllo together with the Ruler3000 3D camera. The result: a tailored solution for quality control in the production of tires.

Fast and precise quality control of tires using 3D vision camera

Quality control of tires – highly precise and compact solutions are essential

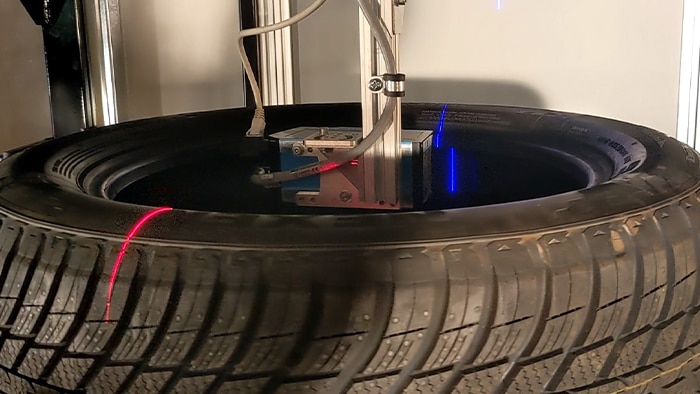

One of the most important application areas for quality control is the automotive industry, where tire inspection presents a particular challenge for machine vision. Both due to the characteristics of the rubber itself (highly absorptive material), and due to the different tire sizes and geometries and the tire sections (inner and outer) to be analyzed. These are tasks that need to be performed at high speed, high resolution, and with a high heterogeneity of defects.

The requirements can therefore vary both in regard to the resolution of the 3D camera and also its size. For example, checking the lettering on the side wall of the tire or with regard to possible defects on the inside of the tire requires a tailor-made system. The system in the form of a compact camera must fit within the inside of the tire.

The approach of Tekna Automazione e Controllo

And this is exactly the challenge the Italian company Tekna Automazione e Controllo set itself. The company has been able to position itself over the years both in Italy and abroad as a system integrator for automation solutions for various industry sectors. “We have continually expanded our market over the years. This gives our customers the certainty that our solutions are based on extensive experience,” says Michele De Stasio, Chairman of the Board of Directors at Tekna Automazione e Controllo.

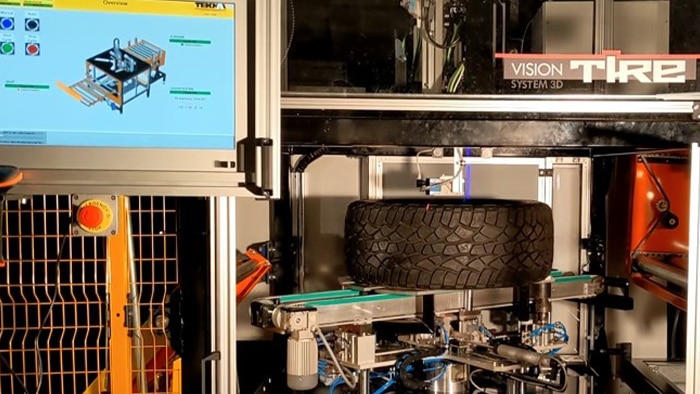

The company started working in the area of image processing several years ago. First with tailored solutions involving the implementation of 3D laser triangulation systems with specially developed solutions and geometries. These are also used for tire defect inspections on their Vision Tire System 3D defects detection machines, which are able to identify defects on the inner and outer surface of the tire, for example scratches, bubbles or deformations.

After consolidating its technology expertise, the company looked for a finished but also reliable solution for reading the lettering on the tire wall. This application is extremely difficult due to the color of the lettering (black on black) and its small size (1 mm x 1 mm x 0.4 mm high).

“Initially we couldn't find a suitable complete and integrated product that offers the same reliability as the solution we developed ourselves,” explains Antonio De Stasio, Head of the Artificial Vision division at Tekna Automation and Control and adds: “After the initial necessary testing, we established that a solution using the Ruler3000 3D vision camera from SICK works. The API provided helped us with integrating the system. Furthermore, SICK is especially valued as a partner by our customers.”

Precision and simplicity thanks to suitable 3D vision camera

The company therefore chose SICK, with whom it already had a longstanding partnership, and the Ruler3000 3D camera. The cameras are able to acquire high resolution images in the shortest possible time. This is achieved using the innovative 2560 x 832 pixel CMOS sensor from SICK with ROCC (Rapid On Chip Calculation) technology that allows a very high scanning speed: Profiles at up to 7 kHz can be acquired over the entire sensor, or even up to 46 kHz with around 100 sensor lines. This enables the Ruler3000 to also record high resolution images in the direction of movement. These very high scanning speeds are also able to be achieved thanks to the high light sensitivity of the sensor, which allows a short exposure time even for highly absorptive materials such as tire rubber.

The Ruler3010 and Ruler3020 variants with medium-sized fields (maximum width of approx. 10 and 20 cm) are especially suitable for checking tire details. An example of this is the special case of the application developed by Tekna Automazione e Controllo for the Vision Tire System 3D labeling machine. The application performs an inspection of the characters on the side of the tire to check their legibility, correctness and integrity based on the tire data sheets. As the system integrator, Tekna Automazione e Controllo integrated the Ruler3000 cameras in the automation structure of the machine. The cameras acquire high-resolution 3D images. The company also developed a custom software for evaluating the correctness (or incorrectness) of the tire wall markings with the help of complex artificial intelligence and machine learning algorithms.

“We would never have been able to achieve this without precise and quickly available data, and we found an ideal partner for this in SICK who met exactly these requirements,” says Michele De Stasio.

Further articles

I want to stay up to date and regularly be informed about new articles!