Not all publicity is good publicity – particularly the publicity found on www.lebensmittelwarnung.de. The website of the federal states and the Federal Office of Consumer Protection and Food Safety (BVL) in Germany publishes product recalls and public warnings from the food and beverage industry on a regular basis – often several times a week. Bacterial contamination in the production, transport, and packaging processes is one of the possible causes. A hygienic system design – and in particular hygienic automation components – can minimize the contamination risks for products and communication risks for manufacturers: Germs and bacteria do not stand a chance against stainless-steel sensors and system solutions from SICK.

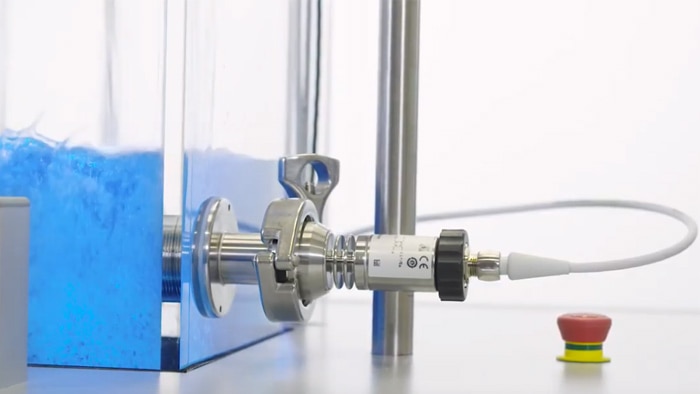

Stainless-steel sensors from SICK deliver exceptional performance combined with compact dimensions, chemical and thermal material resistance, and lasting impermeability. Furthermore, all of the opto-sensory device types in the photoelectric sensor product families, for example, are also available in stainless-steel versions – energetic photoelectric proximity sensors, photoelectric proximity sensors with background suppression, through-beam photoelectric sensors, and photoelectric retro-reflective sensors. The stainless-steel sensor portfolio from SICK also offers suitable solutions for safety technology tasks, the identification of products and containers, position monitoring and path measurement, pressure, temperature, and level measurement, or the inspection of packaging and its contents. These solutions offer the highest level of process reliability for the manufacturer and maximum product safety for the consumer. At the same time, they ensure reliable functioning and consistently high levels of availability even under the harshest application conditions – because the automation tasks must not impact negatively on the hygienic design.