Logistics processes are becoming more complex every day. Transparency is therefore increasingly becoming a decisive requirement for raising the efficiency and productivity of logistical processes. Against the backdrop of transport processes in internal production, mounting and distribution logistics which are becoming steadily more flexible, modular and self-organizing, promptly answering the question of exactly where industrial trucks, transport aids and goods will be located at what time is essential. One option which has already been proven in practice: The localization and analysis technologies from SICK.

Indoor and outdoor localization: Full transparency in the material flow

An important aspect of the vision and reality of Industry 4.0 consists of gathering and evaluating data along the process and value chain and transforming it into information. In order to create a reliable world of data for all types of decisions, preventing system discontinuities which impair transparency, i.e. discontinuities which lead to delayed and non-congruent information in the field and in the IT level, is essential. In intralogistics, such system discontinuities occur, for example, if objects at sources leave a rigid production or assembly line or stationary conveying technology in order to be transported to sinks by mobile transport aids such as lift trucks, manned forklift trucks or tugger trains. In contrast to fixed transport systems, no identification or localization takes place on the way through internal halls and corridors - for the control level, this is a “black hole” in which something could disappear, just like in space. Process efficiency suffers due to the lack of transparency at this point, which can lead to disappearance, delay, delivery to the wrong place or other errors.

Transparency due to integration and fusion of sensor data

Systems for asset localization, which detect the entire movement of goods and make them transparent, can become a real competitive edge for users in that they can avoid process errors, enable continuous and plannable utilization of resources in production, mounting, storage and picking, prevent accumulation of perishable goods or make the complexity of delivery processes manageable. Thanks to coordinated sensor systems for identification, positioning and status detection as well as tools for analysis and visualization, large quantities of data can now be recorded and evaluated constructively. The interpretation of data using Asset Analytics makes it possible to detect the temporal entry and exit behavior of sources and sinks in the material flow, to track the movement of mobile assets on the shop floor and therefore understand complex logistical networks. The goal is to ensure reliable, repeatable and predictable processes throughout the entire material flow – at any time and at any place.

LOCU UWB system: Localization down to the last meter

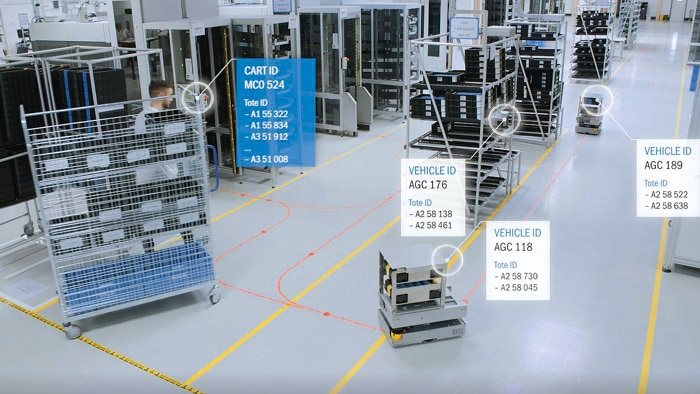

The basic requirement of any localization and asset management solution in logistics - in addition to labeling and identification - is localizing all objects relevant for the material flow. There are various sensor technologies available for this according to the required positioning accuracy and update rate: Some examples are 2D laser scanners, 3D camera systems, line guidance and infrastructure sensors. Relatively new in this portfolio and a key technology at the same time is the LOCU UWB system for tag-based localization. This is a radio system in the frequency band of 3.1 to 10.6 GHz for near-range communication. This very high frequency range enables a very high transmission rate. The sensing range from about 20 to 50 meters makes it predestined for indoor localization, just as the low transmitting power in continuous operation of the UWB antennas (anchors) does. In order to be able to localize an asset, it is equipped with a UWB tag which assigns it a unique identity during localization. If the logistical object is moving in the detection range of several anchors, they can determine the distance to the tag and - similar to nautical cross bearing - identify the position of the assets in space by offsetting the distance values of three antennas. The LOCU achieves localization accuracy of less than a meter here. Every position is given a time stamp, making it possible to completely answer the question of where, what and when.

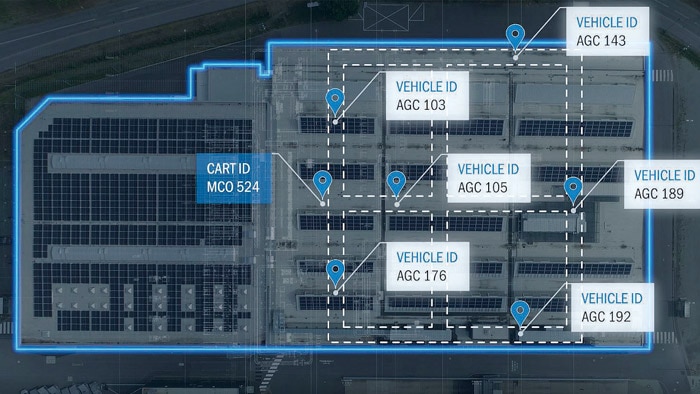

Localization without gaps between indoor and outdoor areas

Material flow and intralogistics do not only take place in closed halls and storage areas, but also often mixed in outdoor areas. When moving outdoors form indoors, the LOCU hands its localization function over to a GPS-supported system solution – the TDC-E gateway system. This multi-sensor networking unit with integrated WLAN, WPAN and mobile communication (GSM 3G+) is typically used on forklift trucks. It collects both process data such as the IDs of load carriers, goods or storage spaces as well as status data of the vehicle and fuses this information together with the GPS localization signal into complete localization information. Quick and complete process and data transparency is therefore ensured in outdoor areas as well.

Asset Analytics or ERP application? Both are possible!

The data from the LOCU and TDC-E as well as any supporting sensor technologies alone does not create added value - but it is the foundation on which asset localization added values can be generated. To do so, the localization and time data of all concerned localization systems must be fused using suitable software algorithms and powerful middleware and interpreted as information. SICK developed the Asset Analytics visualization and analysis platform for this purpose. In addition to the clear display of position, status and other sensor data in real time, it is used primarily for processing the recorded data. In this way, Asset Analytics enables the display of movement profiles, the analysis of transport and downtime and the derivation of optimization potential for process logistics, to name a few examples. Furthermore, an individual result management system can be set up in this analysis tool. This makes it possible to automatically trigger user-defined actions such as notification via SMS or e-mail. An example of this is the localization of objects in pre-defined geo-zones such as receiving work stations or shipping lanes which are only allowed for certain assets or in which defined actions must take place - such as part booking or middleware in an ERP system.

In addition to its own visualization and analysis functions, Asset Analytics offers open interfaces which enable the use of both raw data as well as pre-processed data in company-wide supply chain and asset management as well in as in cloud applications. Thanks to this connectivity, the localization data can also be used on the ERP and MES level for a better understanding of material flows in order to, for example, evaluate the running and transport times between sources and sinks and intervene in the supply chain to optimize it.

Localization makes Logistics 4.0 possible – now!

Localization technologies are one of the key factors in achieving the type of networked logistics needed for Industry 4.0. Localization data provides companies with a high level of transparency and understanding of all production-related assets, load carriers and loading equipment. The payoff: Travel paths can be optimized and adapted dynamically. Setup times can be prepared or scheduled flexibly. The material flow can be planned and controlled, goods movements monitored and storage spaces managed without manual booking processes. Localization data enables agile planning of production and logistical processes for better delivery quality and reliability. The localization and asset management solutions from SICK create consistent transparency of internal delivery processes, open possibilities for higher process efficiency and can create the foundation for new services, even beyond intralogistics.

As a sensor manufacturer with probably the widest portfolio not only for stationary storage and conveyor technology, but also for automated guided vehicle systems, partially-automated industrial trucks and mobile platforms, SICK is also counting on more productivity as well as product and process quality with localization: In its own networked production and distribution locations in Waldkirch and Buchholz as well as the highly-modern, digitally networked 4.0 NOW factory in Hochdorf near Freiburg.

Read more:

Innovative intralogistics: AutoBox with SICK navigation and safety sensors in pilot test at BMW

Safe and rugged: Experts at MAN, HELLER and SICK perfect the deTec safety light curtain

Visionary-B 3D assistance system prevents accidents when driving backwards

Complete sensor solutions for AGC systems in CEP distribution centers

Automated production logistics with automated guided vehicle systems

Bernd von Rosenberger

Senior Vice President Global Industry Center Logistics Automation

Bernd von Rosenberger has been devoting himself to the topic of logistics solutions at SICK since 2001, and is a respected expert in the industry on the subject of "Logistics gets smart". As Director Marketing & Sales, he was responsible for the intralogistics solutions at SICK Inc. for the American market in 2014 and 2015, and since 2015 he has headed the Global Industry Center Logistics Automation at SICK AG.

Greater efficiency in the entire supply chain

I want to stay up to date and regularly be informed about new articles!