Explore our latest innovations and discover SICK's success stories as one of the world's leading solutions providers for sensor-based applications. The SICK Sensor Blog helps its readers stay up to date on the latest advances in automation, ranging from production plants to processes and logistics systems. It’s time to lift the veil on the world of digital transformation.

613 results:

Result 337 - 360 out of 613

The fourth industrial revolution is in full swing. But what effects does it have on companies and what exactly does Industry 4.0 actually mean? We talk about this with Bernhard Müller, our Industry...

Read on

With the increasing interaction between humans and robots in the factory, the collaborative robots (cobots) of Universal Robots are now working closely with the SICK Inspector PIM60, enabling more applications...

Read on

Fieldbus-neutral point-to-point IO-Link communication is growing strongly. The number of IO-Link nodes rose by 47 percent in 2016 alone. IO-Link is thus the first choice for connecting switching devices...

Read on

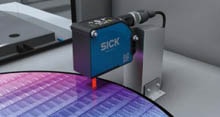

Within the electronics industry, quality and precision are key factors when it comes to intelligent production concepts: The only way to ensure high levels of quality - from the individual components right...

Read on

The darker the object, the harder it is to detect as the distance increases. But penguins in the Antarctic can now keep their black tailcoats on when a drone hovers overhead and the integrated laser scanner...

Read on

In many industries, challenging ambient conditions of all kinds are part of everyday production. The systems and sensors that are responsible for keeping the production process safe have to be specially...

Read on

Industry 4.0 is more than advanced automation. Machines that simply operate more quickly would be Industry 3.5 or 3.6. The fourth industrial revolution, however, takes place on the data level. The idea...

Read on

With industrial parquet manufacturing, fine wood flooring became affordable and available to anyone. The European parquet industry now produces over 80 million square meters of parquet flooring every year...

Read on

Flück, a firm specializing in conveying systems and special-purpose equipment, has modernized a winding and binding machine using sensors and control technology from SICK. At the Geberit...

Read on

Automated and flexible production processes are the answer to increasing quantities, smaller batch sizes, and high production speeds. Automated guided vehicles (AGVs) and their smaller relatives, automated...

Read on

Pieces of plastic in chocolate bars, bacterial contamination of cream cheese, falsely declared ingredients in pasta-based ready meals – a food product may be recalled for any number of reasons. As...

Read on

Confined spaces, tiny objects, and tailored component designs - these are some of the challenges faced when producing electronic components and devices. Intelligent solutions from SICK are exactly the...

Read on

Under the motto “Driving your industry 4ward”, SICK presented its own smart factory at the Hannover Messe 2017 for the efficient production of batch size 1 and showed what is already possible...

Read on

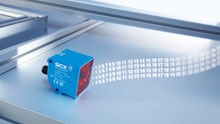

Where most of the contrast sensors reach their limits, the KTS and KTX offer more applications, more areas of use, more flexibility. They incorporate more than just the reliability and availability of...

Read on

Parts of the so-called smart factory are already reality: workstations can coordinate their processes and functions with one another. In other scenarios, production structures are based on autonomous units...

Read on

Angela Merkel’s visit to SICK’s stand provided a highlight right at the start of this year’s Hannover Messe. The German Chancellor stopped off at SICK’s stand during her mandatory...

Read on

The promise was made, and we kept it: For the first time, SICK installed two ultrasonic gas flow meters from SICK in a permanent series connection for a German power supply company. Additionally, the gas...

Read on

Everybody’s talking about Industry 4.0 but few know what it is all about. Bernhard Müller, responsible for Industry 4.0 on the Management Board, and Dr. Kay Fürstenberg, Manager of the...

Read on

Human-robot collaboration (HRC) describes a work scenario in which humans and automated machines share the same workspace and work within it simultaneously. Driven by Industry 4.0, this model promises...

Read on

SICK has more than 30 years’ experience in the field of vision technology. This expertise is exploited in the continuous development of innovative and intelligent solutions for identification, positioning,...

Read on

The networking and availability of data are central features of the digitalization of industry. Data thus free themselves of software and hardware structures, and become independent economic goods. This...

Read on

Reliable function under the toughest conditions - that is the promise from the heavy-duty sensors from SICK. Different product families are available depending on the individual application requirements;...

Read on

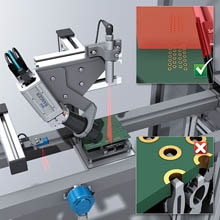

In virtually every country, quality requirements are increasing, innovation cycles are getting shorter, and wage costs are rising. As a result, demand for robot-based automation solutions is growing within...

Read on

Demand for electronic components is constantly growing, in turn increasing the quantities involved in PCB production. To ensure that the connections to the periphery are secure, wire connections are no...

Read on

Result 337 - 360 out of 613

Please wait a moment...

Your request is being processed and may take a few seconds.