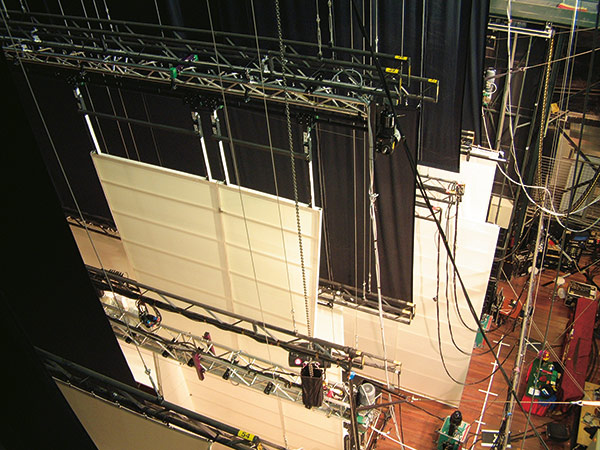

Hoisting walls are installations for lifting and lowering stage sets. In this connection, it is essential that the required path and position data be detected with great precision. ATM60 SSI absolute encoders (multiturn) provide for highly accurate moving and positioning of hoisting walls for stage sets using hoisting winch drives.

Specialists in stagecraft install hoisting walls for lifting and lowering stage sets. Increasingly, automatic controllers implement the upward and downward movement of the heavy scenery. In doing so, they relocate the set parts at a speed of 1.8 m/s. The sequence of movements, in part very complex, must be carried out with high precision. The engineers from the controllers department of a company specializing in stagecraft were looking for rotary sensors capable of detecting the necessary path and position information with great accuracy.

Large basic resolution for high precision

Each hoisting winch is equipped with two extremely robust ATM60 SSI encoders featuring an SSI interface. In this rotary measuring system, a sensor scans permanent magnetic elements mounted on a magnetic reference mark. Due to the large basic resolution of 8,192 steps per revolution, the ATM60 SSI offers high precision. Several reduction gears with magnets mounted on them provide for the encoders multiturn properties. The SSI interface transmits the ATM60 SSIs absolute position to the controller of the hoisting wall automation. The first encoder is located behind, on the hoisting winchs electric motor; the second above, directly on the hoisting winch itself. A safety module constantly compares the two output signals with one another. If the module detects any discrepancies this means there may be a risk of injury for persons located beneath the suspended set part - the movement of the scenery is stopped immediately. This method achieves exact positioning of the automated theater hoisting walls and safety-capable monitoring of the movement of the stage set.

Each hoisting winch is equipped with two extremely robust ATM60 SSI encoders featuring an SSI interface. In this rotary measuring system, a sensor scans permanent magnetic elements mounted on a magnetic reference mark. Due to the large basic resolution of 8,192 steps per revolution, the ATM60 SSI offers high precision. Several reduction gears with magnets mounted on them provide for the encoders multiturn properties. The SSI interface transmits the ATM60 SSIs absolute position to the controller of the hoisting wall automation. The first encoder is located behind, on the hoisting winchs electric motor; the second above, directly on the hoisting winch itself. A safety module constantly compares the two output signals with one another. If the module detects any discrepancies this means there may be a risk of injury for persons located beneath the suspended set part - the movement of the scenery is stopped immediately. This method achieves exact positioning of the automated theater hoisting walls and safety-capable monitoring of the movement of the stage set.

Motors already equipped with encoders

The ATM60 SSI encoders are robust and extremely reliable path and position detection systems. The manufacturer already integrates them into the motors of the hoisting winches at the factory. A safety module compares the values of the encoder on the motor with those of the encoder mounted to the hoisting winch. This provided the prerequisites for fulfilling the SIL3 requirements. In this way, one can obtain the highest possible safety certificate for this type of installation. The stagecraft specialist produces several hundred hoisting winches each year. They are used both in new theater buildings and for modernizing playhouses, theaters, and cultural centers.

- Product information: ATM60 SSI absolut encoder (multiturn)

- Product portfolio: Absolute encoders