In many industries, automated guided vehicles and vehicle systems are making production and logistics processes more flexible. When these vehicles have to be controlled with greater efficiency and precision SICK has exactly the right sensor solutions - however complex they might be. They also meet every requirement when it comes to providing protection in line with standards, protect people against accidents, and help prevent collisions - which in turn keep goods and equipment protected.

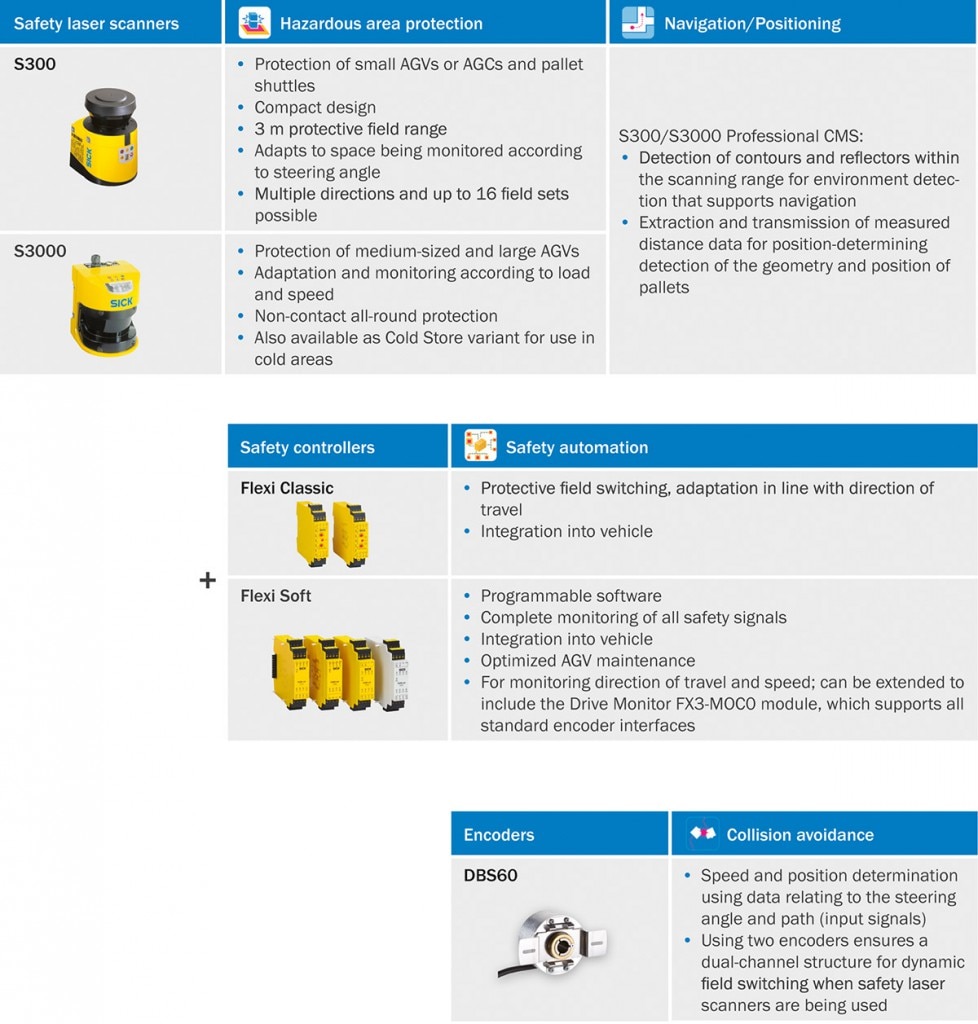

SICK offers modular safety solutions that comply with standards and provide all-round, uninterrupted protection for automated guided vehicles (AGVs) and automated guided vehicle systems (AGVSs) alike - no matter how complex they might be. With safety controllers, reliable and rugged components such as safety laser scanners and encoders can be combined to form a complete safety solution that meets the exact needs of the vehicle type and the task at hand. Laser scanners enable AGVs and AGVSs to navigate and determine positions as well as safety laser scanners are designed to protect people and prevent collisions. Determining object positions and measuring distances are tasks that are equally well suited to this equipment. Thanks to bar code reading systems attached to AGVs and AGVSs, or RFID technology, it is also possible to identify goods and storage places. The enhanced precision and efficiency they create help reduce downtimes and boost productivity, ensuring processes remain smooth and safe - and their applications go beyond simply the fields of production and logistics.

Modular safety solutions for all-around protection of AGVs and AGVs, conforming to standards

Click to enlarge. All data without guarantee.

Safety solutions that comply with standards

Risk assessments in line with specifications by the relevant legislative authority need to be performed on each AGV and AGVS to determine exactly which risks they do pose. This information is then used to identify the protection or safety measures that are necessary for meeting all the safety requirements of ISO 13849/EN 1525 (soon to become ISO 3691-4). Safety technology from SICK ensures that AGVs and AGVSs offer this protection in line with standards - even at an international level (EU, US, and CN standards).

Relevant standards and directives for AGVSs and AGVs

- Maschine Directive 2006/42/EC

- EN/ISO 13849-1

- EN 1525 - Automated Guided Vehicles (C-standard), soon to be ISO 3691-4

- VDI 2510 - Automated Guided Vehicles Systems (AGVSs)

- VDI FA309 - Guidelines for AGVs Safety

- International: Turkey GB10827.1999, GB/T30029-2013, US ANSI B56, EU EN 1525

Whats next?

Safety solutions by SICK are easy to integrate into existing safety concepts and are fit for the future thanks to their ability to be extended at any time. It used to be that AGVSs were given a somewhat restricted range of jobs in production logistics, assembly, and hospital logistics, but in the future they are set to break beyond these boundaries, taking on additional tasks not only in these conventional environments but also in new applications, where service is at the fore and the systems are coming into contact with staff who have no training in using them, Dr. Günter Ullrich, VDI expert committee AGVS, FORUM-FTS reports. The lines between autonomous driving as it is used in on-road applications and in service robotics are becoming blurred. Vehicles are becoming more intelligent because this is what users expect from automated systems nowadays. Sensors have to be three-dimensional and have the capability to generate and process data flows in significant quantities. Not only that, but it must be possible to combine them with sensor systems.

- Product information: S300 safety laser scanners, S3000 safety laser scanners, Flexi Soft Safety controllers, Incremental Encoder

- Product portfolio: Safety laser scanners, Safety controllers, Laser measurement Technology