Motor-controller communication in electric drive technology is at the verge of a digital evolution. The new HIPERFACE DSL® interface (DSL stands for Digital Servo Link) saves costs, offering at the same time a maximum degree of security of investment and machine safety. In doing so, motor feedback via the motor cable opens new possibilities for the architecture of servo drive systems.

Change of technology through digital evolution

Servo drive systems in electric drive technology consist of, among other things, the two components of controller and motor. To date, the two were connected to each other using two separate connection cables for power supply and data transmission. Integrating both cables and thus being able to do without one of the two connection plugs was a wish frequently expressed by many manufacturers of motors and controllers, which SICK now fulfilled with HIPERFACE DSL®. The interface is no longer hybrid, i.e. structured analog-digital, but enables for the first time purely digital communication between the frequency converter and the motor feedback system - using a minimum of connection lines.

HIPERFACE DSL® EKS/EKM 36 rotary motor feedback system

HIPERFACE DSL® EKS/EKM 36 rotary motor feedback system

Digital data transmission: two cores in the motor cable suffice

The interface allows robust data transmission, immune to interference, between the controller and the motor via two cable cores integrated directly into the motor cable measuring up to 100 m. Data communication is modulated on to the supply voltage of the motor feedback system. It occurs synchronously to the controller cycle, which may be as short as 11.95 µs. In addition, it is possible to transmit the values of other sensors, e.g. of a sensor for measuring winding temperature, via the digital motor feedback protocol. Special techniques and the use of pulse transformers ensure the encoder signal is decoupled from any interference on the motor output cable.

Benefits for motor producers, machine builders, and end users

In terms of appearance, one can recognize electric drives featuring motor feedback systems and integrated HIPERFACE-DSL® interface by the fact that they use only one device plug. Accordingly, the system requires only one motor cable, cutting cabling costs for machine builders in half. Another aspect is that the element no longer required also does not use up space any more. This applies both to stockpiling in the machine builders warehouse in terms of materials management and, e.g., to the space required for energy chains in the machine: The trailing cable installation becomes significantly smaller.

In terms of appearance, one can recognize electric drives featuring motor feedback systems and integrated HIPERFACE-DSL® interface by the fact that they use only one device plug. Accordingly, the system requires only one motor cable, cutting cabling costs for machine builders in half. Another aspect is that the element no longer required also does not use up space any more. This applies both to stockpiling in the machine builders warehouse in terms of materials management and, e.g., to the space required for energy chains in the machine: The trailing cable installation becomes significantly smaller.

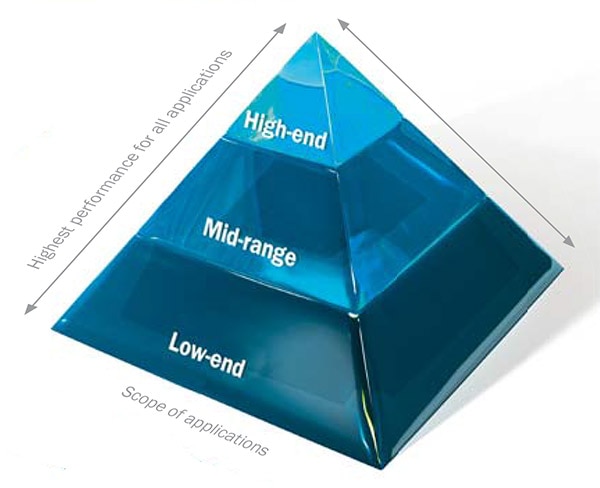

New possibilities for energy savings and downsizing

Moreover, less hardware in the shape of connector plugs, cables, and periphery on the servo drive reduces its mass. For applications in which the drive needs to be moved along in a dynamic process, this constitutes a decisive argument, for in this context, less mass or weight, respectively, equals less kinetic energy. In many applications, the servo drive can be designed one size smaller. This downsizing supports the trend towards increasingly more compact machines, a trend emerging in many industries. Furthermore, a drive in a lower rating class is generally beneficial in terms of price as well.

Minimized risks of error and condition monitoring improve availability

Minimization of the connecting lines between the frequency converter and the motor feedback system as well as the reduced installation effort have the advantage of featuring fewer sources of error. Just by virtue of this fact, they have significantly reduced technical risks from a purely statistical perspective. In turn, this constitutes one of the reasons why HIPERFACE DSL® allows for greater availability of machines. Another reason is the option for machine builders to develop and offer, along customers lines, an individual and continuous condition monitoring of the servo drive and thus, of this sector of the machine. This approach is used not only directly on the machine. As an option, users have remote access to the machine at any time via the DSL Analyzer Tool and the data transmission by web interface. Permanent condition monitoring opens up great potential for saving operating costs, since one is not required to check and replace critical machine components preventatively. At the same time, the condition data of the drive constitute the basis for defining necessary maintenance measures in coordination, e.g. with the production plan or the dates for scheduled downtimes.

Integrated SIL safety and the latest technology guarantee future security

In terms of safety technology, data transmission via HIPERFACE DSL® is certified for applications up to SIL3 (IEC 61508) and performance level e (EN ISO 13849-1), respectively. This ensures that in principle, the digital motor encoder interface can be used in safety applications as well. HIPERFACE DSL® is on its way to becoming tomorrows standard - thats how great the benefits of HIPERFACE DSL® are with respect to technology, economic efficiency, and security of investment.

In terms of safety technology, data transmission via HIPERFACE DSL® is certified for applications up to SIL3 (IEC 61508) and performance level e (EN ISO 13849-1), respectively. This ensures that in principle, the digital motor encoder interface can be used in safety applications as well. HIPERFACE DSL® is on its way to becoming tomorrows standard - thats how great the benefits of HIPERFACE DSL® are with respect to technology, economic efficiency, and security of investment.

- Product information: HIPERFACE DSL®, HIPERFACE DSL® EKS/EKM36 motor feedback system rotary

- Technolgies: Motors and Controllers with HIPERFACE DSL®