Burning vehicles in tunnel tubes are among the horror scenarios in traffic reports. The Hot Spot Detector made by SICK features integrated LMS511 laser measurement sensors can detect overheated vehicles and vehicle components prior to entering the tunnel and send out a warning signal to the control center. By means of an automated diversion process, the connected traffic management system prevents the vehicles from entering the tunnel. Thus, fire and accident disasters in the tunnel can be avoided in time.

What stands out only on closer inspection several hundred meters ahead of the northern Karawanks Tunnel portal, below the old Austrian customs roof, is a Hot Spot Detector unique in all of Europe. Developed by SICKs new subsidiary, ECTN AG, it is used on a daily basis by the Austrian highway operator ASFINAG to guarantee road safety. The Hot Spot Detector combines measurement data from thermal imaging cameras and laser measurement sensors to detect overheated vehicles in free flow traffic before entering the tunnel. In this way, it makes a significant contribution to preventing vehicle fires in the tunnel. Overheating on the vehicle - so-called hot spots - is localized accurately and, if necessary, signaled as an alarm.

Generation of a 3D thermal model

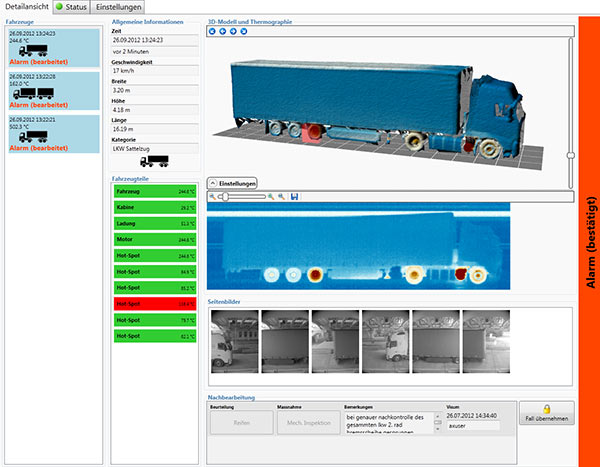

Vehicles exceeding 7.5 t in weight are guided on the truck lane through the Hot Spot Detector to the toll station in order to undergo metrological detection at full speed. Using the LMS511 laser measurement sensors from SICK, every vehicle is measured geometrically, with a 3D model generated and the vehicle classified in one of 28 vehicle classes. Infrared cameras measure the temperature from both sides. The temperature values are combined with the 3D data of the vehicle to generate a 3D thermal model. Thanks to this combination, the Hot Spot Detector software is capable of automatically detecting different vehicle components such as load, exhaust system, or wheels, comparing them individually with the temperature threshold values designated for each respective vehicle component.

Specific hot spot detection

Distinguishing different vehicle components allows sensitive alarming with a minimum number of false alarms. For instance, in case of a motor coach, the engine is located to the rear of the vehicle. Thanks to the classification, the software knows it is dealing with a bus and that the increased temperature at the rear, caused in this vehicle by the engine, is completely normal. In the area on and around the wheels, too, dangerous overheating may occur, caused by defects of the bearings or the brakes, though in some cases also due to improper use of the brake system. The Hot Spot Detector can recognize wheels and thus distinguish hot spots, such as overheated wheels exceeding approx. 100 °C, from hot components of the exhaust system, eventually issuing an alarm signal.

Click to enlarge

Click to enlarge

1. The graphic representation of the alarms on the user interface allows users to assess the situation quickly and take the necessary measures.

2. In this instance, the overheated axle on the trailer triggered the alarm, the two "cold wheels" show cracked brake discs.

Hot Spot Detector at the Karawanks Tunnel proves its worth

The Hot Spot Detector installed at the northern entrance of the Karawanks Tunnel by the Austrian highways operator ASFINAG has already proven its worth only one week after being armed. A semitrailer truck with a wheel exceeding 200 °C on the trailer triggered the alarm as it passed through the Hot Spot Detector. Closer inspection indicated that in addition to the overheated brake, the vehicle was also traveling with two cracked brake discs. Police imposed an immediate driving ban on the vehicle. The detailed graphic representation of the 3D thermal model allowed operators in the tunnels control center to assess the situation and issue instructions to the diverted vehicle operator via the intercom system.

Fire hazard averted

Bulkscan® LMS511 laser volume flowmeter

Bulkscan® LMS511 laser volume flowmeter

The Hot Spot Detector from SICK - a guarantee for more road safety. The tried and tested products from SICK, such as the LMS511 for all-weather use in outdoor areas, contribute a considerable share to this end. A similar installation is also under consideration for additional tunnel systems within the ASFINAG network - particularly those with two-way traffic or extended uphill or downhill grades.

- Product information: Bulkscan® LMS511 laser volume flowmeter

- Traffic solutions: Safety, Electronic Toll Collect, Vehicle Dimensioning