Vision sensors usually inspect the quality of a product - whether in industrial production or in food-processing companies. However, the sensors from SICK's Inspector product family can also be used in production to provide technologically advanced process control in a variety of ways. Lantmännen Unibake, an industrial bakery in the Belgian city of Moeskroen, produces croissants and other small baked goods. Lantmännen uses the vision sensors to ensure the different products receive a faultless glaze.

Lantmännen Unibake is a Swedish company, but its industrial bakeries are spread all over the world. As part of a takeover in 2006, the company purchased three production sites in Belgium: Brussels, Londerzeel, and Moeskroen. "Here in Moeskroen we make croissants, chocolate croissants, flaky pastry swirls, and other Danish pastries for the B2B market," explains Project Engineer Maarten Dedeurwaerder. "We send our products, already frozen, to customers all over the world and more locally too, to the retail trade, hotels or for specific events. Once at their destination, they are baked to a finish." From left: Matthias Deslee (SICK Sales Engineer), Andy Verbeken (Software Engineer Lantmännen), Maarten Dedeurwaerder (Project Engineer Lantmännen)

From left: Matthias Deslee (SICK Sales Engineer), Andy Verbeken (Software Engineer Lantmännen), Maarten Dedeurwaerder (Project Engineer Lantmännen)

You eat with your eyes first

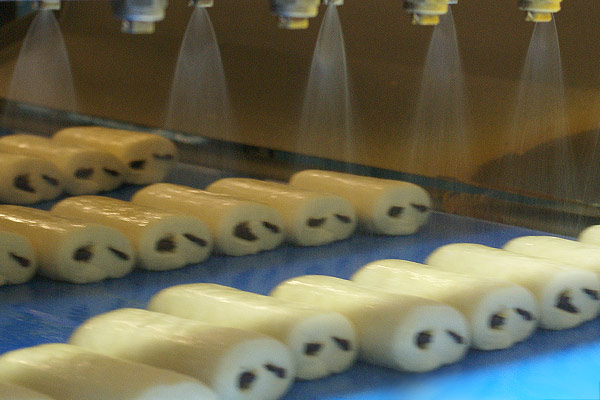

It is the golden-brown, shiny coating which makes croissants and other pastries look so appetizing. The glaze consists of stirred whole egg or egg yolk, which is sprayed onto the product shortly before it enters the oven. In the context of industrial production, the application of this glaze presents a problem which should not be underestimated. One reason for this is the high speed at which the belt transports rows of the products. For one thing, the glaze is relatively expensive and should be applied sparingly. But when spilled egg glaze is caught in order to feed it back into the system, air often gets into the mixture, causing unwanted frothing. And for another, feedback systems of this type are very labor-intensive in terms of hygiene and maintenance. So before setting up a new production line, Lantmännen Unibake wanted to get a little help. The glaze needed to be applied to the products being transported on the belt in a manner which was extremely precise and well controlled. The entire production process runs largely automatically, with mobile systems applying the corresponding filling or topping according to the recipe in question. "On our new production line, spray heads sprinkle the water or apply the egg glaze. A multi-head spray device has been installed across the entire width of the belt and each individual spray head can be controlled separately," says Maarten Dedeurwaerder. "This enables us to ensure that the liquid arrives on the product accurately and as little as possible is lost, which has made a feedback system surplus to requirements now."

Inspector recognizes templates

A vision sensor from SICK's Inspector product family determines the position of the individual products on the belt. The products are laid next to one another in rows of six or eight, but never in a perfectly straight line. Shortly before the spraying process, the vision sensor determines exactly whereabouts on the belt the products are positioned. The spray heads are then activated and deactivated precisely in accordance with this information. The technology integrated in the Inspector enables messages to be sent to the v (PLC) in real time, thanks to lightning-fast image analysis. The PLC then controls the spray heads on an individual basis.  Andy Verbeken programmed the application: "The Inspector maps the entire width of the belt. Within this space we have defined different zones, which correspond to the areas that the spray heads can reach. A simple algorithm counts the number of pixels in each zone in order to establish whether a product is located inside it at that moment in time. If a product is indeed within a particular zone, the associated spray head is activated quick as a flash, with the delay involved depending on the respective belt speed." A complex control system regulates this application. Therefore, when observing the process it becomes clear that the spray head is activated a little earlier or later, depending on whether the product is positioned at the front or back of the row. In other words, the spray template is fully adapted to the position of the individual products on the belt.

Andy Verbeken programmed the application: "The Inspector maps the entire width of the belt. Within this space we have defined different zones, which correspond to the areas that the spray heads can reach. A simple algorithm counts the number of pixels in each zone in order to establish whether a product is located inside it at that moment in time. If a product is indeed within a particular zone, the associated spray head is activated quick as a flash, with the delay involved depending on the respective belt speed." A complex control system regulates this application. Therefore, when observing the process it becomes clear that the spray head is activated a little earlier or later, depending on whether the product is positioned at the front or back of the row. In other words, the spray template is fully adapted to the position of the individual products on the belt.  In practice, however, the Inspector's integrated functionality meant that there was no need for any overly complex programming work. The innovative thing about the system is the way in which the zones can be defined in the images recorded by the camera, facilitating 1:1 coordination between the images taken in the zones and the activation of the spray heads.

In practice, however, the Inspector's integrated functionality meant that there was no need for any overly complex programming work. The innovative thing about the system is the way in which the zones can be defined in the images recorded by the camera, facilitating 1:1 coordination between the images taken in the zones and the activation of the spray heads.

External illumination

One problem in applications using vision sensors is illumination. If the lighting is insufficient, the quality of the images suffers, which of course means that the sensor cannot function optimally either. "As soon as the belt became wet, mirror effects caused problems because the camera could no longer detect the products clearly," explains Maarten Dedeurwaerder. "So we decided on external illumination using an LED strip, which lights the belt in such a way that reflections are prevented. The belt concerned is blue. By setting the color intensity accordingly, it wasn't difficult for us to identify products uniquely." The new technology represents a great improvement for Lantmännen Unibake over the feedback system it was using previously. The process can be controlled better, which not only ensures improved product quality, but also means that production itself runs with far fewer faults now. Therefore, the Inspector, which will initially be used just on the new production line, will in future be implemented on the other lines too.

One problem in applications using vision sensors is illumination. If the lighting is insufficient, the quality of the images suffers, which of course means that the sensor cannot function optimally either. "As soon as the belt became wet, mirror effects caused problems because the camera could no longer detect the products clearly," explains Maarten Dedeurwaerder. "So we decided on external illumination using an LED strip, which lights the belt in such a way that reflections are prevented. The belt concerned is blue. By setting the color intensity accordingly, it wasn't difficult for us to identify products uniquely." The new technology represents a great improvement for Lantmännen Unibake over the feedback system it was using previously. The process can be controlled better, which not only ensures improved product quality, but also means that production itself runs with far fewer faults now. Therefore, the Inspector, which will initially be used just on the new production line, will in future be implemented on the other lines too.

- Product information: Inspector vision sensor

- Product portfolio: Vision sensors

- Website: Lantmännen Unibake