Being a reliable and proficient partner to the oil and gas industry, SICK has revolutionized the natural gas distribution in the last four years. Before the market launch of the FLOWSIC500 in 2012 it was mainly conventional technologies that were put to use by public utilities and large-scale industrial consumers such as rotary piston and turbine gas meters. Several thousand SICK FLOWSIC500 devices have so far been put to use around the world for natural gas measurement by users hailing from a variety of industries - with success and high customer satisfaction.

From the outset, the FLOWSIC500 ultrasonic compact gas flow meter was specifically designed for natural gas distribution applications requiring verified calibration. The development posed new challenges, especially the requirement where the new ultrasonic gas flow meter had to be capable of integration into existing pipework systems without straight inlet or outlet pipes. This is because, in comparison with the large measuring stations bars used by gas transportation firms, the measuring points of the gas distribution companies are very compact and normally do not have sufficiently long and straight sections of pipework.

New avenues in product development

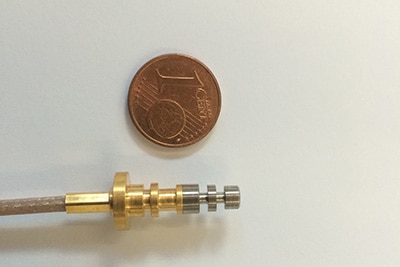

In order to keep the gas flow meter as compact as possible, miniaturized, high-frequency ultrasonic transducers made from titanium were developed by SICK in-house. These ensure immunity against background noise and, together with the electronics, bring the underlying low-power concept to fruition. This in turn enables autonomous battery operation with an electrical power consumption of just 0.05 watts. This makes it possible to use the FLOWSIC500 in stations where no external power supply is available.

Instead of arranging the flow conditioning and measuring section in sequence in a straight section of pipe, the SICK development team guided the gas flow from the pipe axis and then back into the pipe axis after measurement. This meant that they could dispense of the previously required straight inlet pipes upstream of the meter completely and arrange the meter components adjacent to each other in a compact configuration. In addition, sufficiently stable and loss-free flow conditions had to be created in the smallest amount of space in order to carry out the measurement. The starting point of the optimization was therefore defined such that no requirements could be placed on the integration characteristics. The ultrasonic gas flow meter should always perform measurements to the same degree of accuracy, whether the device is installed in a long section of pipe, behind any bend, or behind a cross-sectional jump of the pipework.

Innovative technology for demanding applications

The development is innovative for a further reason: the first gas flow meter replacement concept released by SICK onto the market. Unlike conventional devices, the components of the flow conditioning, ultrasonic sensors, and electronics that are relevant to the measured values are together housed in a cartridge, which can be replaced by the user and which constitutes the actual gas flow meter. The (cartridge) adapter of the FLOWSIC500 can remain in the pipeline in the event of a replacement. This novel device concept has the advantage that the gas flow only has to be interrupted for a very brief period of time in the event of any required re-calibration or maintenance work. With minimal installation effort, the user can easily replace the old gas flow meter with a new one and resume operation after only a brief interruption. This also allows the implementation of ring replacement concepts and therefore the optimization of user-specific operational processes. The available sizes and dimensions of the FLOWSIC500 also enable quick and easy substitution of conventional rotary piston and turbine gas meters without having to apply any design modifications to the pipeline. Because the measuring ranges are higher and inlet or outlet straight lengths are unnecessary, the device can be used to make the design of new measurement stations significantly more compact than was previously possible.

The ultrasonic gas flow meter was also equipped with a further innovation in the form of an additional self-diagnostics function, where the built-in electronics constantly compare the values from the measurement and diagnostic system. Special operating software called FLOWgate500 was developed in order to fully analyse and visualize these diagnostic capabilities. The software features numerous useful tools for commissioning, maintenance, and recalibration. The electronics of the FLOWSIC500, which can be operated autonomously for over five years using a battery pack, also replaces other systems for flow conversion, because in addition to the operating volume it also measures the pressure and temperature of the natural gas and therefore calculates the standard cubic meters required for the invoicing of natural gas.

Approval in many countries worldwide

With respect to gas flow meters, this primarily involves compliance with country-specific pressure-equipment, explosion-protection, and metrology regulations such as PED, ATEX, IECEx, GOST, MID, OIML, and many more. FLOWSIC500 is therefore also approved in numerous countries beyond Europe, including the Russian Federation, the CIS (Commonwealth of Independent States) and in the US.

Equipped for the digital future

In contrast to conventional technologies, the FLOWSIC500 ultrasonic gas flow meter impresses with its minimal maintenance requirements, ease of use, and its extensive diagnostic capabilities, which all ensure measurement with long-term stability. Another success factor which accounts for the growing share of tried-and-tested ultrasonic technology in the market segment of natural gas distribution is mainly the cost optimization achieved by the FLOWSIC500 in light of the ultrasonic gas flow meters previously available on the market, justified without having to accept compromises in terms of measurement accuracy and reliability.

- Product information: FLOWSIC500