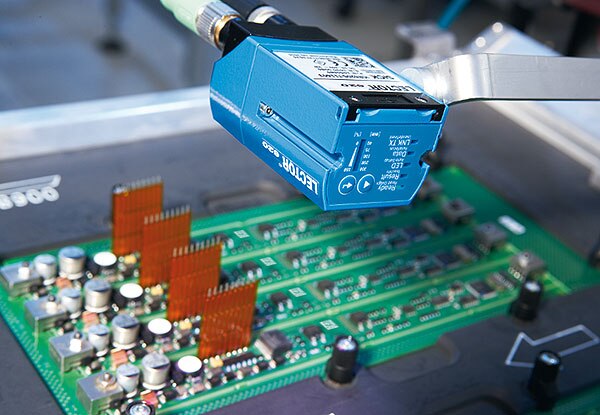

In the testing processes for wireless radio modules of a producer known worldwide, the LECTOR®620 image-based code readers from SICK very reliably identify even poorly printed Data Matrix codes on printed circuit boards

Hardly any other market shows miniaturization advancing more rapidly than electronics devices. The reduction of external dimensions goes hand in hand with increasingly marked reduction in the size of electronic components and assemblies on the inside. At the same time, production figures of wireless radio modules, e.g., are rising constantly, and manufacturing and testing processes are becoming faster all the time. This makes special demands on the technologies used for identifying and tracking electronic assemblies, since the markings - generally, two-dimensional Data Matrix codes - are becoming increasingly smaller as well. Thats why one of the worlds largest electronics corporations relies on the LECTOR®620 from SICK: Even in case of short read times and small codes with a resolution of only 0.15 mm, the camera-based code reader delivers read rates exceeding 99 percent - even if the code and contrast quality of the miniature label leaves much to be desired.

LECTOR®620 stands the test ten thousand times every day

Compact design, industry-compatible integration into diverse IT environments, intuitive operation, and top reading performance for reliable track & trace make the LECTOR®620 the efficient solution for demanding code reading. This also applies to identifying printed circuit boards for wireless radio modules of the type used in smartphones or tablet PCs. Before integration into these devices, each assembly is put to the test one final time. The PCBs are marked with tiny glued-on Data Matrix codes that can be identified extremely reliably using the LECTOR®620: With more than 10,000 printed circuit boards processed a day, the code reader achieves exceptionally high read rates. What makes this possible is the real-time decoding of all images of a Data Matrix code captured at 60 Hz. In addition, during operation the LECTOR®620 is capable of autonomously readjusting a combination of up to four reading parameters, such as, e.g., brightness and contrast settings. Consequently, the device adapts automatically to fluctuating code qualities, thus avoiding no reads. This approach allows optimum read results in PCB identification at any time.

- Video: Reading of damaged Data Matrix codes with the LECTOR®620

- More videos: LECTOR®620

Simple integration into test systems

In this application, the LECTOR®620 is guided by industrial robot kinematics, enabling it to identify codes at distances between 40 to 300 mm. Integration into the test facility and commissioning turned out to be very simple because operation is intuitive to an extent unrivalled. Laser points visualize the center of the image, allowing rapid alignment. Using pushbuttons mounted on the device, one can start auto setup, i.e. an autonomous teach-in process. In doing so, the LECTOR®620 parameterizes itself, which enables the device to identify the respective code. Since the code reader also illuminates the reading field with red and blue LEDs, one can manage without external sources of light. The inspection results can be saved on an insertable 32 GB Micro card. This constitutes a great benefit, for instance, with a view to quick and convenient parameter cloning or when updating firmware. The LECTOR®620 is the innovative and efficient solution for reading and testing 1D and 2D codes - not only in the electronics industry.

- Product information: LECTOR®620 image-based code reader

- Product portfolio: Image-based code readers (1D/2D/OCR)