Public bodies ask for full and accurate reports: has the company in question adhered to the limits for environmental emissions at fossil fuel power plants, hazardous waste incineration plants, and biomass-based power plants? Simple-to-use data acquisition systems that are not susceptible to faults or failures are therefore crucial for companies operating this type of facility. The MEAC data acquisition system by SICK is reliable and popular with customers, providing them with a solution for the continuous recording, analysis and transmission of emission data. Expert service included.  Conventional power plants, renewable energy plants, and smaller, decentralized energy systems: this is what the electricity production landscape currently looks like in Germany. However, just like everywhere else in the world, large fossil fuel power plants still play a significant role. Burning fossil fuels does not necessarily have to have a negative effect on the environment. The cleanest fuel with the lowest level of CO2 emissions is in fact natural gas. Now, coal-based power plants are moving with the times and investing in new technology to reduce the amount of harmful substances in emissions. Products like dust filters, desulfurization units, and nitrogen removal systems detoxify flue gases. saving primary energy means increasing the efficiency of the combustion process and thus increasing the energy efficiency. Increasing the efficiency automatically reduces the amount of CO2 emissions. Based on an energy output of one third a few years ago, the tendency is now pointing towards a level of around 50% today. The remaining 50% is lost as residual heat.

Conventional power plants, renewable energy plants, and smaller, decentralized energy systems: this is what the electricity production landscape currently looks like in Germany. However, just like everywhere else in the world, large fossil fuel power plants still play a significant role. Burning fossil fuels does not necessarily have to have a negative effect on the environment. The cleanest fuel with the lowest level of CO2 emissions is in fact natural gas. Now, coal-based power plants are moving with the times and investing in new technology to reduce the amount of harmful substances in emissions. Products like dust filters, desulfurization units, and nitrogen removal systems detoxify flue gases. saving primary energy means increasing the efficiency of the combustion process and thus increasing the energy efficiency. Increasing the efficiency automatically reduces the amount of CO2 emissions. Based on an energy output of one third a few years ago, the tendency is now pointing towards a level of around 50% today. The remaining 50% is lost as residual heat.

Renewable energies

Protecting the environment by reducing emissions: that is the current goal for the energy supplier Mark-E. A regional energy company based in North-Rhine Westphalia, Germany, Mark-E runs several power plants in a number of locations fueled by coal, gas, water, wind, and solar power. The company pened the region's first power plant run on biomass back in 2004. For its CO2- neutral energy production processes, Mark-E uses up to 600 t of scrap wood and other biogenic waste every day, some of which is provided by a local paper factory. When compared to a coal-burning power plant, this corresponds to around 160,000 t less carbon dioxide emitted every year. However, Mark-E also uses coal, natural gas, and oil for its heating plants. The authorities make sure that the plants adhere to legal limits.

Comprehensive documentation

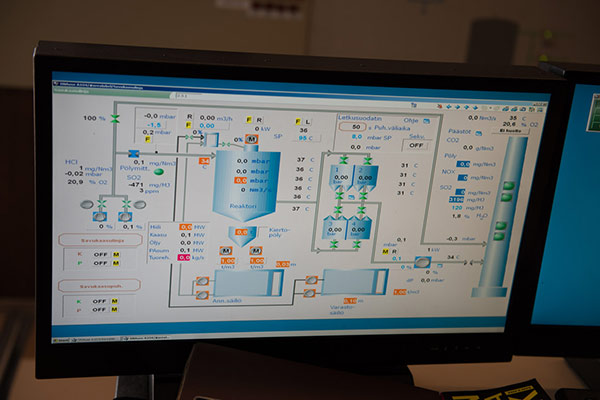

The quality of emissions has to be monitored and analyzed over time so that comprehensive documentation can be provided to the environmental authorities. Mark-E counts on SICK's reliable, tried-and-tested emission data management system for this purpose that records data safely, calculates, analyzes, and displays figures, and transmits data remotely. It records measured values and operating data on a second-by-second basis and stores it on a continuous basis. Mark-E has been working happily with the MEAC data acquisition system since 2007. so that it can continue to report environmental data in accordance with the new German guidelines for the uniform practice for monitoring emissions, Mark-E has decided to upgrade the MEAC2000 to the MEAC2012 in all of its plants.

The MEAC2012 meets all requirements set out under current German legislation and automatically implements these rules in conjunction with the individual settings for the customer's system. The data from all measurement points is recorded remotely and then analyzed. It is transmitted on the company's internal network and compiled on a central PC so that it can be read off easily from one location. Mark-E also expressed its interest in a reduced network - SICK forwards all data directly to Mark-E's central server so that the power plant managers do not have to spend lots of time going back and forth to coordinate the various parties. The individual Mark-E power plants do not have to worry about transmitting emission data to the local authorities either. The MEAC2012 does this automatically by transferring the daily means and event reports to the authority's system via a modem. And the environmental officers and system operators do not need time to get to grips with a new system: the customary user-friendly MEAC design remains the same and all existing data can continue to be displayed.

The MEAC2012 meets all requirements set out under current German legislation and automatically implements these rules in conjunction with the individual settings for the customer's system. The data from all measurement points is recorded remotely and then analyzed. It is transmitted on the company's internal network and compiled on a central PC so that it can be read off easily from one location. Mark-E also expressed its interest in a reduced network - SICK forwards all data directly to Mark-E's central server so that the power plant managers do not have to spend lots of time going back and forth to coordinate the various parties. The individual Mark-E power plants do not have to worry about transmitting emission data to the local authorities either. The MEAC2012 does this automatically by transferring the daily means and event reports to the authority's system via a modem. And the environmental officers and system operators do not need time to get to grips with a new system: the customary user-friendly MEAC design remains the same and all existing data can continue to be displayed.

High-speed information is the key to availability

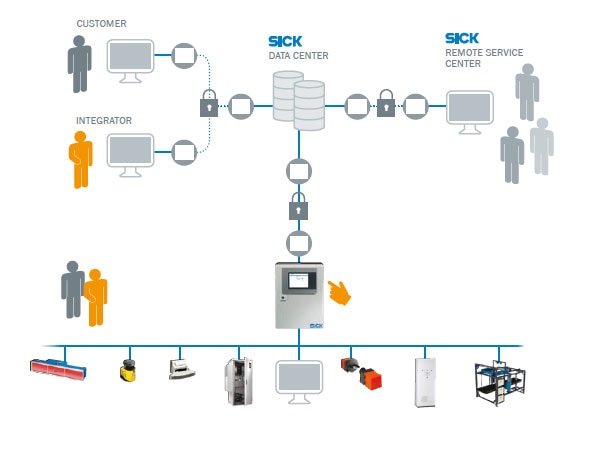

The Meeting Point Router (MPR) is the connection hub for all data recording units and machines incorporated into the remote service system. Mark-E's second key objective is to keep all downtime risks as low as possible, not just in production and for the measuring devices, but also in service. This is where safe remote maintenance can help to solve many problems. SICK's web-based remote maintenance system meets all the require-ments issued by the German office for Information security (the BSI) and is therefore completely safe. Its demands on Mark-E's firewall are kept to a minimum. The Meeting Point Router (MRP) is the connection hub for all data recording units and machines incorporated into the remote service system. The user simply has to press the MPR touchscreen to request SICK to carry out remote maintenance. A SICK service technician will then be on hand within a specified response time to provide the user with help and advice for remote service. Mark-E is connected to SICK's web-based Remote service center via highly encrypted data channels with HTTPS and SSH authentication standards. connection reports can be viewed on the portal at any time. As such, Mark-E can always see who has requested remote service and when a remote maintenance session has been carried out.

The Meeting Point Router (MPR) is the connection hub for all data recording units and machines incorporated into the remote service system. Mark-E's second key objective is to keep all downtime risks as low as possible, not just in production and for the measuring devices, but also in service. This is where safe remote maintenance can help to solve many problems. SICK's web-based remote maintenance system meets all the require-ments issued by the German office for Information security (the BSI) and is therefore completely safe. Its demands on Mark-E's firewall are kept to a minimum. The Meeting Point Router (MRP) is the connection hub for all data recording units and machines incorporated into the remote service system. The user simply has to press the MPR touchscreen to request SICK to carry out remote maintenance. A SICK service technician will then be on hand within a specified response time to provide the user with help and advice for remote service. Mark-E is connected to SICK's web-based Remote service center via highly encrypted data channels with HTTPS and SSH authentication standards. connection reports can be viewed on the portal at any time. As such, Mark-E can always see who has requested remote service and when a remote maintenance session has been carried out.

- Product information: MEAC Emission data evaluation system

- Product portfolio: CEMS solutions