Clothes make the man, so says the proverb - but only if they fit. Despite the vast number of available sizes, it is sometimes difficult to find a shirt, pants, a dress or a skirt that fits perfectly. Custom-made and yet affordable clothing - this circle is to be squared with mass customization. Therefore, several apparel and sportswear manufacturers rely on body scanners to collect body measurements with sensors such as the LMS400 laser scanner from SICK.

The LMS400 from SICK is a laser scanner that is used in industrial applications, e.g for volume measurement, in freight and parcel handling or to detect location and position in palletizing and de-palletizing applications. XX Production online GmbH in Breuna, a market leader in bicycle measurement systems, uses the LMS400 in their Body Scanning CRM body scanners. There they capture individual factors such as height, length of the spine, width of the shoulders, circumference of the head, waist and hips, and other features of the male and female body.

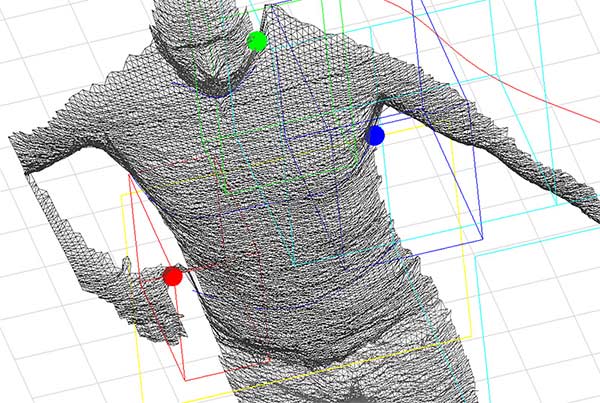

In the Body Scanning CRM system, the LMS400 is moved up and down at a steady speed along a travel path of 2.2 meters to scan the person from the front and back. From a distance of approximately one meter, a completely safe laser beam captures all the relevant body measurements in a few contact-free scans lasting four to seven seconds each. Based on the 2D contour information provided by the laser scanner and its rate of traverse, a point cloud is created in three-dimensional space. The Body Scanning CRM system uses the point cloud to create a 3D model of the person and collects the anthropometric data of the relevant body parts as information for e.g. apparel manufacturing.

Point cloud created from the data provided by the laser scanner

The LMS400 is a compact laser class 2 laser scanner. The emitted light is fanned out and the object or surface reflectivity is evaluated. Angular resolutions that can amount to 0.1° and scanning frequencies of up to 500 Hz - can be parameterized to optimally perform the task. The same applies to the measurement field: Scanning angles are freely definable between 0° and 70°. The data of the body scan are transferred to the processor of the Body Scanning CRM system and stored there for the manufacture of the customized product. A software program additionally allows customers to make individual choices regarding, for example, the color and cut of the product. The measuring system is not only being used for custom sportswear and running shoes, but also for the optimal ergonomic adjustment of bicycles and bicycle saddles. It is even possible to scan car drivers before they move the car and to transfer the data via Wi-Fi to the vehicle, which then automatically adjusts the drivers seat, seat back angle, head rest and lumbar support to the ideal position. Thus, body scanners such as the Body Scanning CRM pave the way for a new production and sales method of articles that, for various reasons, require a customized fit: mass customization. More personal than off-the-shelf products, but not subject to the production and logistics costs of batch size 1″ - manufacturers of sportswear and safety clothing or uniforms, for example, manage to define personal shoe and clothing sizes based on a number of optional and individual parameters and to produce apparel based on these measurements in an economically feasible way. The modular design and manufacture of the respective articles make this possible. Standardized mass-produced components are combined with individualized modular components to create a customized end product - and that with stable, cost-efficient processes in production and logistics. Many apparel companies, which (have to) define different standard sizes for each continent, show great interest in such objective 3D-measuring methods and the respective results. Using data on population-specific body dimensions and proportions, they can optimize their sizes for different markets worldwide.

- Product information: LMS400 2D laser scanner, Body Scanning CRM

- Product portfolio: 2D laser scanners

- Customer information: XX Production online GmbH