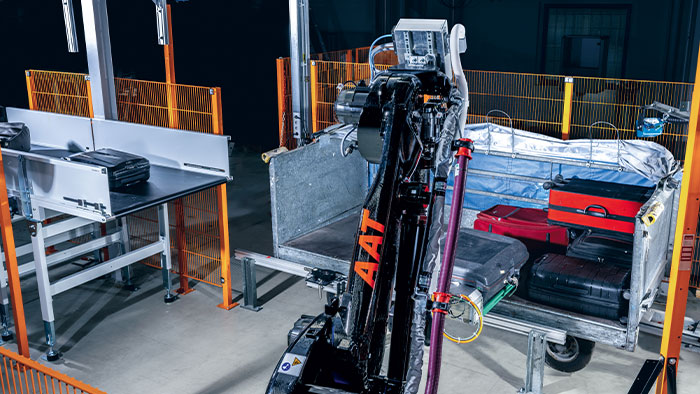

At the Amsterdam Airport Schiphol, robots handle passengers’ baggage. The ABLE system made by AAT Automation uses robots to reliably load baggage from the conveyor system into a ULD container. To do their job, the robots need precise data about each bag’s form and position as well as about available space in the ULD container. Now a 3D camera from SICK delivers this data. Featuring 3D snapshot technology, the Visionary-T Mini helps the system load baggage faster and more precisely.

3D cameras take automated baggage loading to the next level at Schiphol airport

AAT’s ABLE system loads airport baggage

Day in and day out, countless pieces of baggage are loaded at airports all around the world. Every hour, an average of 50 bags weighing a total of one ton are moved by a single service worker.

There’s a better way to handle baggage at an airport: The Automated Baggage Loading Equipment system (ABLE) from AAT Automation has been demonstrating this for years now. The system uses an industrial robot to take each piece of baggage from the conveyor system and place it in the waiting baggage container. Other systems for loading containers in operation at airports are limited to providing airport staff with lifting assistance or helping as movable roll conveyors. In contrast, the ABLE system’s robots work fully automatically. The system frees airport personnel from having to perform hard physical labor and guards against health risks.

Everything done with precision: locating, gripping, setting down

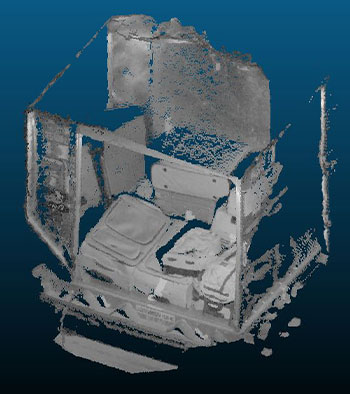

Delivering peak performance when loading baggage means the ABLE system must locate each piece of baggage, calculate its dimensions and pick it up from the conveyor system. Then the system must determine the position of the ULD container and how to load it. In the final step, the robot finds a custom fit for the baggage in the container. To enable the system to work with such precision, AAT Automation had started equipping it with SICK sensors several years ago.

But airport requirements are increasing: Processes must become more and more efficient, while the variety of goods transported increases. Further enhancements became necessary to ensure the system would also work quickly and reliably in the future as the complexity of tasks has continued to rise. Thanks to the fast and precise 3D cameras from SICK, the new generation of AAT’s ABLE system will also be able to load far more pieces of baggage reliably and smoothly. The cameras will also boost precision in capturing the shape of the baggage.

Reliable 3D data raises efficiency

The Visionary-T Mini 3D time-of-flight camera stands out for its performance: The 3D camera not only delivers up to 30 high-precision depth images per second that are ready for processing in a blink of an eye. The camera also captures the entire image area in just one “snapshot.” This shortens processing times by eliminating the swiveling operation that was required when the system used laser scanners.

AAT Automation has equipped the ABLE system with six Visionary-T Mini cameras. Thanks to their wide dynamic range and high 3D data quality, the cameras ensure the system quickly and accurately detects each piece of baggage even in challenging conditions such as reflective surfaces. The compact design also allows for a wide range of installation options, thus offering a significant degree of design freedom.

Successful partnership

For more than 25 years, AAT Automation has been delivering automation solutions in a broad range of areas, including conveyor technology, robotic systems and mobile transport systems. These are used, for example, in logistics automation applications at airports such as Amsterdam Airport Schiphol.

The addition of innovative 3D cameras to the ABLE system is another example of the value created by the technology partnership between SICK and AAT Automation. The collaboration offers decisive advantages for immediately addressing new business requirements with state-of-the-art technology. Future AAT Automation projects for airports could be using 3D cameras from SICK as well. Possible fields include measuring technology and automated guided vehicles (AGVs) — both core areas of competency for the two companies.