The requirements on extractive gas analysis are demanding. Not only on the quality of the analysis, but also the availability and functionality of the highly sensitive devices used. This is of great importance for production reliability, however it can often impose a very high burden on the operating costs of a company. To minimize the investment costs for customers – in the cement industry in the present example – SICK offers an on-site warehousing system for important spare parts called Smart Parts, which has the advantage of shifting costs to times of actual demand.

Smart Parts efficiently shifts costs in spare parts provisioning

Apr 14, 2020

What good is the best and fastest 24/7 service in the world if, at the decisive moment, important spare parts are missing? To counter a negative response to this question with an intelligent solution, SICK has developed for its customers an on-site warehousing system that ensures the availability of devices and analyses while at the same time taking the financial burden off the customer.

A good example of this is emission measurement in cement production. SICK offers two certified extractive gas analyzers for this – the MCS100E and the MERCEM300Z – that fulfill the statutory requirements for the operating entity. Due to the complexity of these systems, however, companies need to rely on service technicians for maintenance and any necessary repairs. Setting up an in-house spare parts warehouse by purchasing critical parts would represent a large investment for the customer. Tied-up capital that is unavailable for the day-to-day business. Smart Parts therefore allows customers, for example in the cement industry, to minimize their long-term capital expenditure (CAPEX) and transform it into operational expenses (OPEX).

Cost shifting in two ways

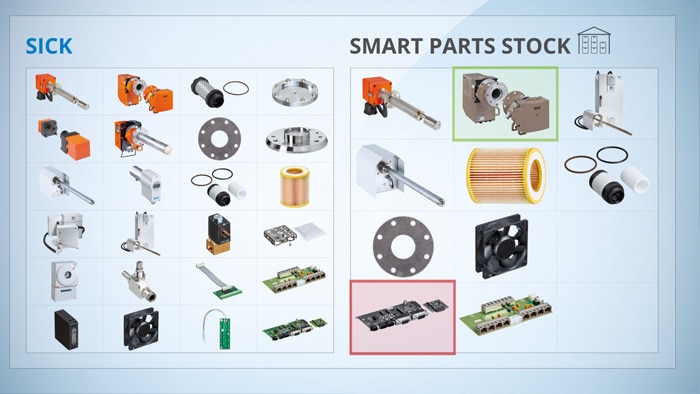

To provide the fastest possible access to critical spare parts, SICK has taken the following approach for the cement industry as well: a spare parts warehouse is set up directly at the customer’s site, whereby the parts remain the property of SICK until they are withdrawn by the customer or the technician on-site. When no demand exists, the customer pays only a provision fee. A choice is offered between a customer-specific set of spare parts, a complete replacement device, or both. For costly devices of correspondingly complex construction, having such an exchange unit available directly at the customer’s site can be quite advantageous. Firstly, it guarantees a 100% availability, and secondly the customer does not need to keep a replacement device of their own on hand.

Custom spare parts package on site

SICK assumes the responsibility for checking all spare parts that are critical to the application. This applies, in particular, to very expensive and sensitive parts that may have a very long replenishment lead time. At the same time, SICK assembles a custom spare parts package for the customer based on his requirements, then sets up the spare parts warehouse on site and checks it annually. All the customer needs to do is provide the storage space, and ongoing access to it for SICK service technicians deployed on site.

High availability of the emission measurement

Smart Parts therefore means only having to purchase things that are actually needed. This guarantees the same availability as purchasing to stock, but with significantly lower costs. Thanks to these fast response times and extended options, potential downtimes or plant shutdowns with possible contractual penalties can be avoided in the cement industry. On account of the great success of this solution, two production locations in Germany are now equipped with Smart Parts. A third location is planned.