If all the pieces of a jigsaw puzzle fit together, what emerges is a beautiful picture. Renowned automation specialist fpt Robotik has combined its new patented gripper with SICK’s Visionary-T 3D camera to solve a specific type of automation puzzle – but unlike a jigsaw, the project wasn’t just started for fun. Through this professional collaboration, fpt Robotik has been able to design a completely new robot cell for pick-and-place applications, closing the gap in robot-based picking of non-rigid and dimensionally unstable products, particularly pouches. The sophisticated gripping technology has made it possible to singulate and place products that are unable to achieve a tight vacuum seal and for which no automation solutions have been available so far – and it does all this while handling the products with care. Reliably detecting the positions of the products requires the right vision system, and for this, the robotics manufacturer has turned to the Visionary-T AG. After just under a year of successful development work and comprehensive support from SICK in the process of implementing the technology in the cell, the results really are a beautiful picture.

Finding an automated process that is able to pick pouches of various shapes and sizes, and with varying contents, has always been a difficult challenge to overcome. Now, fpt Robotik has developed a reliable solution for detecting, gripping, and setting down pouches: its Subito Connect A cell combined with the smart Visionary-T AG 3D camera from SICK. First unveiled to the public at the Automatica 2018 trade fair in Munich, the robot cell is compact, flexible, and mobile, and can be installed easily at manual workstations as well as logistics or picking workstations alike. So it comes as little surprise that the solution has had an extremely positive reception on the market, with big-name companies – including a major German games manufacturer – registering their interest in it.

In the process of seeking out an expert partner to provide camera-based gripping technology, fpt quickly turned to SICK and its Robot Vision products. A company focused on “Sensor Intelligence.”, SICK’s many variants of its Visionary-T technology provide the market with highly competitive camera solutions. The 3D camera is comparable to 3D snapshot solutions delivered by other competitors – but it is more cost-effective by far. As a result, its excellent value for money was one of the key factors in fpt choosing SICK.

Superior gripping thanks to 3D technology

Particularly in pick-and-place applications involving non-rigid surfaces and surfaces that are unable to achieve a tight vacuum seal, the devil is often in the details – and the same is true in the specific case of gripping and setting down packaged puzzle pieces. Solutions for executing intricate, complicated applications like this require several small steps in order to be reliable. These steps are themselves pieces of a larger puzzle, and they need to be put together correctly in order to reveal the right picture. fpt Robotik and SICK successfully united their skills and expertise in this area, reaching a real milestone in cooperation. Both sides delivered exceptional standards of skill, assuredness, persistence, and professionalism in incorporating the Visionary-T AG camera into the Subito Connect A cell. After just under a year of working closely together, the staff members involved in the project were able to bring the gripper and camera combination up to a dependable standard for series production.

Cell-based collaboration

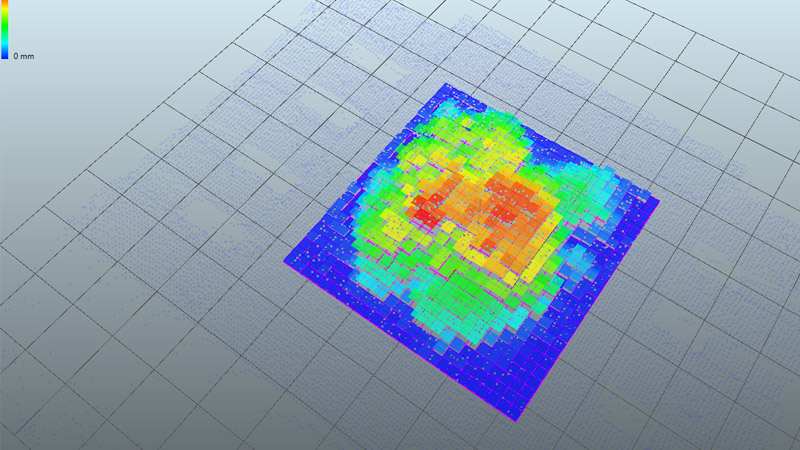

In the cell itself, the application’s success is all thanks to the seamless way in which the individual components are able to work together. The 3D data captured by the camera is prepared and converted immediately, right at the point where it is created. To achieve this, the Visionary-T is equipped with ultra-high-performance hardware plus a range of special image processing filters that allow it to reliably detect the spatial positions of dark, transparent, or reflective objects. Once it has precisely identified the positions in this way, it communicates them instantly to the machine controller using straightforward global 3D coordinates, at a rate of up to 50 images per second.

The data is prepared in a way that accommodates a direct link between the camera and the programmable logic controller, which in turn allows the patented gripper to operate at its full potential. With one product successfully integrated into the other, achieving guaranteed singulation of products is now easy.

Implementing intelligence

Andreas Frick, project manager and corporate strategist at fpt Robotik, gives his perspective on the technology in this business field: “Robots can do so much. But until now, it just hasn’t been possible to use them for automated handling of non-rigid parts, and they haven’t always been successful in detecting pouches. Now, we have a gripper and camera working in perfect harmony – which means that we have an actual product that works in an application that used to be impossible for robots to deal with.” His words demonstrate perfectly how solving an application like this – the Subito Connect robot cell, in which gripping and setting down need to take place quickly – is a puzzle made up of several small pieces that need to fit together. During their involvement in the project, SICK employees were able to have significant input in the system’s intelligence through the camera technology that they introduced. The biggest indicator of the project’s success, however, is the way in which the SICK and fpt Robotik teams worked together and kept thinking one step ahead. It is now hoped that the teams will build on this collaborative project to bring about yet more innovative solutions and tangible success stories in the near future.