Tea with a pure, natural taste: That is every tea drinker's dream. And now, thanks to the Italian company TEAMAC, that dream can become reality. The machine manufacturer provides environmentally friendly packaging solutions for tea, which preserve the natural, unadulterated flavor of the beverage. All of the sensor technology in the packaging machines is supplied by SICK.  China is known as the birthplace of tea. The beneficial effects of the tea leaf were described there around 5,000 years ago. Today, tea is the most popular beverage in the world, with an annual global production of 3.5 million tons. After water, tea is the drink that we consume most frequently. The invention of the tea bag contributed significantly to this development. The first precursors to the tea bag were created by the New York tea importer Thomas Sullivan, who sent his customers tea samples packaged in small gauze bags in 1908. These gauze bags proved to be a resounding success. At the end of the 1920s, single-chamber tea bags made by sticking together pieces of special parchment appeared on the market. These products were better because the paper that was used had no effect on the taste, but the after-taste of the glue still bothered the fine palates of discerning tea drinkers. The double-chamber bag appeared later on. This bag was made by folding filter paper of the highest quality, and the tea was placed in two chambers. This allowed the full flavor of the tea to be released. So tea in bags began taking the world by storm.

China is known as the birthplace of tea. The beneficial effects of the tea leaf were described there around 5,000 years ago. Today, tea is the most popular beverage in the world, with an annual global production of 3.5 million tons. After water, tea is the drink that we consume most frequently. The invention of the tea bag contributed significantly to this development. The first precursors to the tea bag were created by the New York tea importer Thomas Sullivan, who sent his customers tea samples packaged in small gauze bags in 1908. These gauze bags proved to be a resounding success. At the end of the 1920s, single-chamber tea bags made by sticking together pieces of special parchment appeared on the market. These products were better because the paper that was used had no effect on the taste, but the after-taste of the glue still bothered the fine palates of discerning tea drinkers. The double-chamber bag appeared later on. This bag was made by folding filter paper of the highest quality, and the tea was placed in two chambers. This allowed the full flavor of the tea to be released. So tea in bags began taking the world by storm.

Innovation from Packaging Valley

The Italian company TEAMAC specializes in the manufacture of machines for packaging tea. The company was founded in 1993 by the engineer C. A. Daunisi and is located near Bologna in what is known as Packaging Valley. Daunisi built a machine which indeed packages tea in environmentally friendly bags, but nevertheless the pure, natural flavor of the beverage was preserved to the best possible extent.  True innovation - tea bag without staples

True innovation - tea bag without staples

He developed a completely environmentally friendly and biodegradable tea bag for this purpose. The bag is made entirely of natural filter paper and is sealed with two simple knots on the string, to which the label is also attached. This solution does not use any adhesives, which can dissolve in the tea, or items such as staples for sealing.

Environmentally friendly packaging with no staples

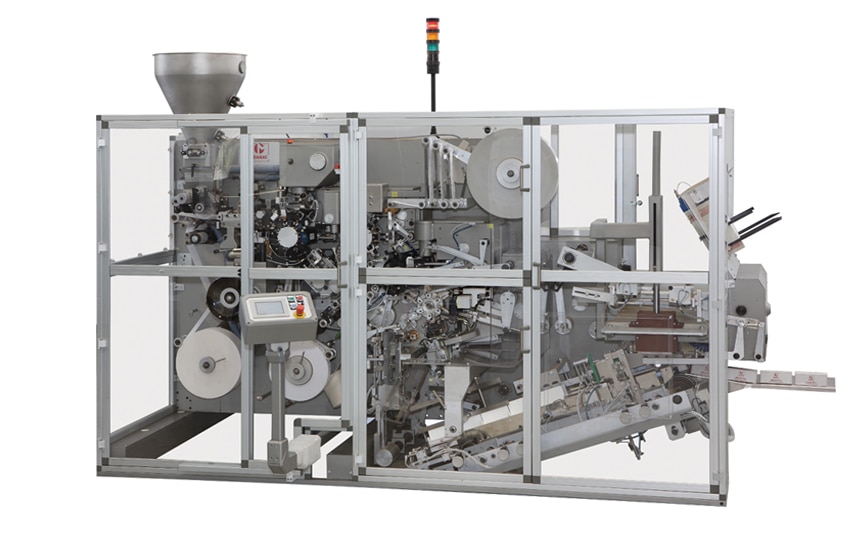

TEAMAC offers two different special-purpose machines: MD20 and MD20 Plus. The MD20 focuses primarily on simplicity, while the MD20 Plus is geared more toward flexible production. Both machines avoid using staples to attach the string to the bag and label. One model manufactures double-chamber bags which are packaged in a separate heat-sealed sachet. It can be fitted with a counter for manual removal or an automatic packaging unit at the end of the production line. TEAMAC MD20 Plus - packaging machine for tea with SICK sensor technology

TEAMAC MD20 Plus - packaging machine for tea with SICK sensor technology

The other machine manufactures simple double-chamber bags as well as bags packaged in a separate heat-sealed or knurled sachet. It can also be fitted with an optional unit for automatically inserting, opening, filling, and sealing boxes with one or more rows of pre-counted bags. Both models can process all types of boxes (flip-top, tuck-in, etc.) - including special shapes and completely sealed variants with a tear opening.

Maximum efficiency by using robust and flexible sensors

All of the machine parts are produced in the Gruppo Marchesini's own production facilities in Italy. This makes it possible to achieve quality, efficiency, and reliability for a production rate of 200 units per minute, in any configuration. With the sophisticated technology of its knotting system, TEAMAC has brought about a noticeable drop in production costs. In comparison with the competition, both the material consumption and the need for spare parts are significantly reduced. With this in mind, the demands placed on the diverse sensor technology used in the machines are intense. From the basic sensor technology to complex systems, all of the TEAMAC machines are fitted exclusively with SICK products. CM30 capacitive proximity sensor

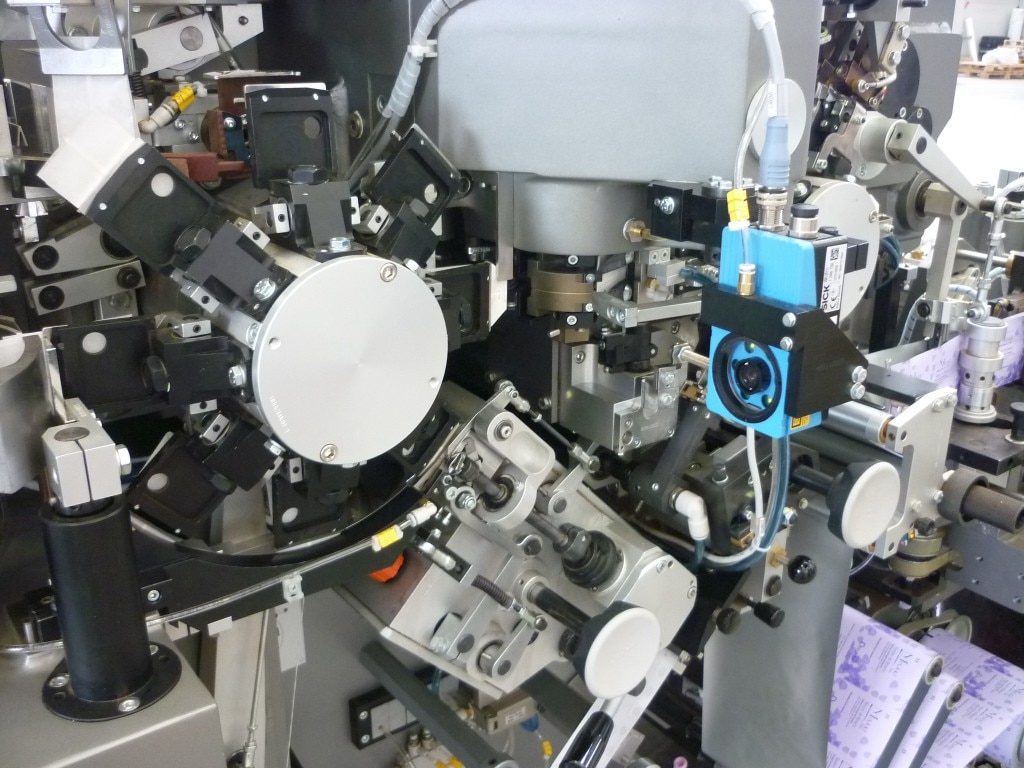

CM30 capacitive proximity sensor

The sensors perform a huge range of functions, from sorting the tea leaves with the help of the CM30 capacitive proximity sensor to detecting the moving filter paper for the bag with the KTM contrast sensor. In addition, SICK technology helps to speed up material changes in the machines, thus reducing downtime and optimizing production costs. With the simple, flexible installation of these sensors, materials, printing options, and colors can be changed in a matter of seconds.

Detecting the smallest of errors: The vision becomes reality with the vision sensor

To further improve quality assurance, TEAMAC uses the Inspector 2D vision sensor from SICK. The Inspector inspects the seal as well as the bag itself, and uses pixel control to reliably separate flawless products from sub-standard goods. Due to its high working speed and consistently quick response time, the Inspector can check the products with the machine at maximum speed without affecting production capacity. This ensures smooth operation, even in dusty environments where properties such as reliability, low maintenance, abrasion resistance, and resistance to cleaning agents are required. Inspector 2D vision sensor: quality inspection with the help of pixel control

Inspector 2D vision sensor: quality inspection with the help of pixel control

The Inspector vision sensor really is a unique product in terms of its development and integration into our machines. Since our bags are sealed with a knot, we need sensors that can detect even the smallest of errors. The Inspector is able to perform precisely this kind of inspection, explains a TEAMAC technician. We are very happy that we chose the Inspector vision sensor, because the system performance has remained constant over the years and is not impaired by dust. With this sensor, the reliability of our machines is absolutely guaranteed.

- Product information: CM30 capacitive proximity sensor, KTM contrast sensor, Inspector 2D vision sensor

- Product portfolio: capacitive proximity sensors, contrast sensors, 2D vision