Over the past few years, the number of people suffering from food allergies has risen significantly. To ensure that every pack really does have on the inside what it states on the outside, vision sensors from SICK's Inspector product family visually inspect every product that leaves the belt at Crops in Belgium. The frozen food manufacturer is therefore able to guarantee that consumers with particular food allergies will always have access to the right information.

Left: Tino Blancke (Projects Teamleader Crops), right: Matthias Deslee (Sales Engineer SICK Belgium)

Left: Tino Blancke (Projects Teamleader Crops), right: Matthias Deslee (Sales Engineer SICK Belgium)

"We do absolutely everything we can to make sure that customers can consume our products with no worries at all," says Tino Blancke, who is responsible for Production division projects at Crops. Crop's is one of Europe's leading companies when it comes to manufacturing and distributing frozen products. As well as its production site in Ooigem, the group also owns several other manufacturing facilities, which freeze large quantities of vegetables and fruit. These frozen products are then further processed and packaged in Ooigem as mixed stir fry vegetables, gratins, and ready meals, among other things. Crop's brings a large proportion of these products to market as store brands. "Our production sequences are subject to careful and comprehensive quality control, which includes the declaration of all ingredients on the relevant packaging. This means that retailers are taking no risks whatsoever in purchasing our products. If a product should be packaged incorrectly or not have all the ingredients listed on it, the entire batch is recalled without delay."

Integrated functions

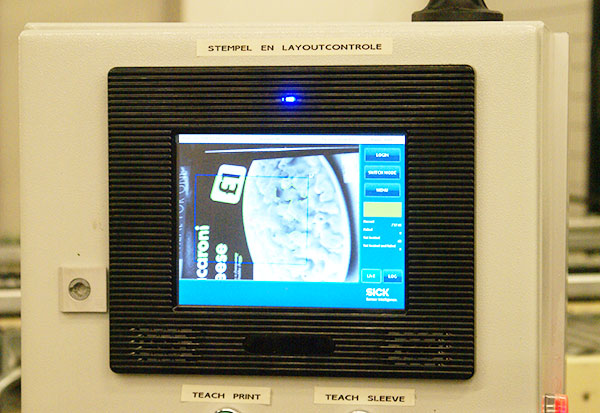

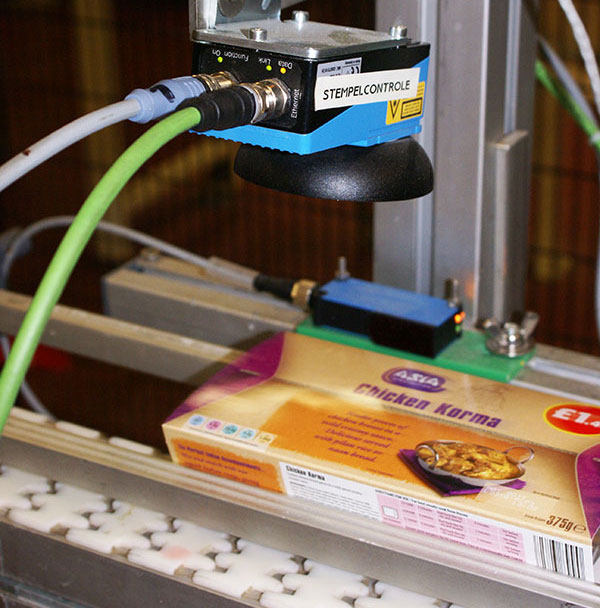

"Each packaging line is equipped with two cameras," explains Tino Blancke. "One camera inspects the packaging as a whole and checks that the product sleeve has been applied correctly. The second zooms in closer and makes sure that the batch number and expiry date have been printed correctly.

The Inspector vision sensor from SICK has the great advantage that it features integrated functions, which enable these processes to be implemented quickly and easily in practice. The teach-in function is used in checking the packaging. Each time the line has been changed over, an employee checks that the new packaging meets specifications. He then issues a command to the camera system that the packaging which follows must correspond to the recorded parameters. If there is any deviation, the camera transmits an error message and the line is stopped. The batch number is checked by counting pixels in the code window. If the result is too low, the product is ejected from the production line automatically."

100 products per minute

Thanks to this incredibly practical approach, Crop's has been able to reduce its error rate in terms of final packaging inspection to zero since introducing the system. All starting products are delivered to Crops already frozen and there they go into interim cold storage at -21 °C. The production processes cover the mixing of ingredients and marinating, whereby the frozen goods chain is not interrupted. Multi-head weighers then measure out the semi-finished products. Next they are filled into bags or trays, then fed to the packaging system and, finally, to the spiral freezer. From there, they are transported back into storage. In order to ensure the cold chain is not interrupted, such a cycle only lasts between just under 15 and 30 minutes. Quality control has thus to be performed within this narrow time window too. Therefore, up to 100 products pass the lens every minute and the evaluation must be performed inside a fraction of a second. This is made possible thanks to the basic functions provided by the intelligent Inspector vision sensor.

Traceability of the quality assurance system

"The operator simply has to select the right previously defined reference for each type of packaging," says Tino Blancke. "A particular reference is assigned to each format, and this specifies which section on the packaging the camera has to check. Several screens are available in the production hall, where operators can call up the images generated by the cameras. This enables us to make sure that the correct reference has been selected and that the camera is able to take a useful picture of the packaging.

The system learns which packaging is currently needed anew for each production sequence via the teach-in function. This results in a particularly high level of flexibility and therefore guarantees a 100% accurate final inspection through to the end of the production line. If a customer changes the label layout, which happens on a regular basis because we manufacture products for store brands, the system is able to learn the parameters for the new layout automatically. As a next step we are planning to integrate all aspects of quality control, that is, check weighers, metal detectors, and the new vision system, into a higher-level quality assurance system so that we can also ensure seamless traceability for product control itself."

Trailer: Inspector vision sensor

- Product information: Inspector

- Product portfolio: Vision sensors

- Customer information: Crop's