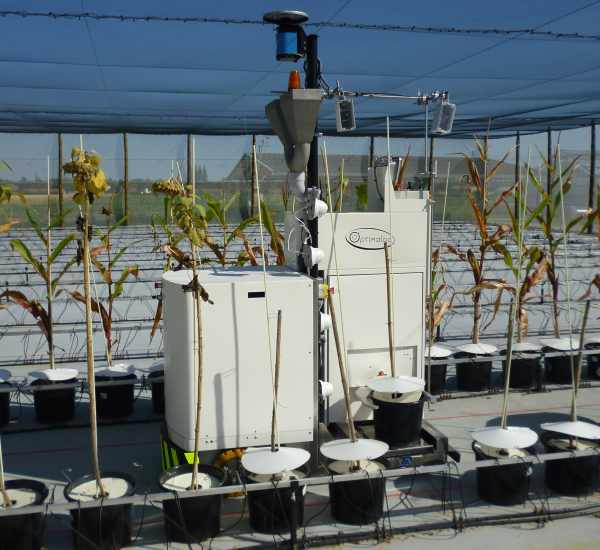

Optimalog was founded in 2006 and develops specialized automation software for PCs. They are currently developing a robot that can fully automatically cultivate an agricultural research park for the French National Institute for Agricultural Research (INRA) in Toulouse. All of these required functions are based on integrated equipment from SICK. (with video)

The robot moves outdoors along the paths between the plant holders, and detects, grips, weighs, photographs, and waters the holders automatically according to the instructions of the researchers, which they transmit directly from their workstations. The robot automatically fills its 70-liter water tank and charges its high-performance battery as necessary. It uses a weather station to monitor climatic conditions and reacts accordingly, interrupting its work if necessary.

Tailored equipment from SICK

NAV350 navigation scanner

NAV350 navigation scanner

All of these functions are based on integrated equipment from SICK. First and foremost, the NAV350 navigation scanner is mounted on top of the robot. Using reflective marking points and a wide scanning range, the scanner continuously calculates its position so that the robot can orient itself. Type UM18 ultrasonic sensors (3 at the front and 3 at the back) ensure optimal movement and are used by the AGS to avoid obstacles. Sensors connected to a navigation module issue all required instructions to the robot, so that it moves freely and reaches the plant holders to be examined. An OD Value short-range distance sensor is fitted to the Heliaphen to detect the plant holders.The robot uses a laser beam to analyze the curvature and depth of a holder in order to locate it quickly and precisely. For this purpose it uses a CLV bar code scanner, which reads the bar code on the holder to ensure that the robot has targeted the correct plants. The robot then places the plant holder back in its exact theoretical position (which is not necessarily the position where it picked up the plant holder) with a measurement accuracy of 5 mm.The AGS is fitted with type IN300 Direct inductive safety switches (2 at the front and 2 at the back), which control the position of the bumpers. If the switches are triggered, the information is sent to a type UE10-2FG safety relay, which activates the emergency stop pushbutton.

Cost reduction and maximum flexibility

The robot Heliaphen provides a number of benefits. Thanks to equipment from SICK, this extremely flexible and precise robot is excellently suited to its environment and the tasks to be carried out. The arrangement of the plant holders, their size, and distances can all be changed without extensive installation work. The researchers therefore have maximum flexibility in conducting their plant tests. The robot can be put into operation quickly, works at high speed, and does not require costly infrastructure.

Video Robot Heliaphen:

- Product information: NAV350, UM18, OD Value, CLV-Scanner, IN3000 Direct, UE10-2FG

- Product portfolio: Indoor laser measurement technology, Ultrasonic sensors, Short range distance sensors, Bar code scanners, Inductive safety switches, Safety relays

- Customer information: Optimalog

- Video: NAV350 Navigation scanner