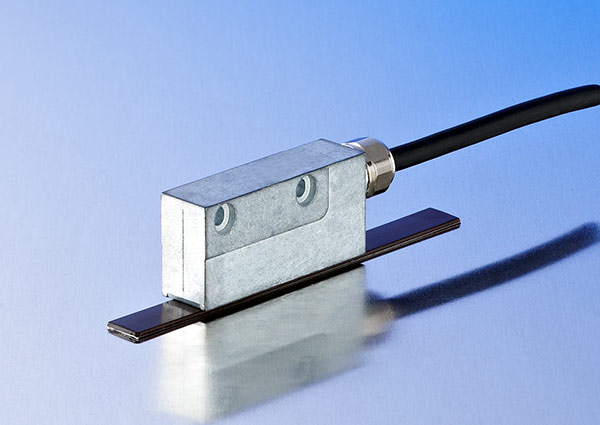

The new TTK50 is one of the most compact motor feedback systems for linear direct drives. With its highly reliable movement speed, it ensures the highest dynamics with the absolute position detection of linear axes.

Compact linear motors with movement paths up to 1 m are widely used in diverse applications such as electronic manufacturing and assembly equipment, Pick-and-Place machines or packaging machines. These compact systems are largely equipped with incremental measurement systems since the design of the currently available absolute measurement systems are frequently too large.

As absolute, space-saving and precise measurement system for linear movements, the TTK50 is the answer to the market requirements for compactness and performance. The linear motor feedback system offers top class performance data: movement speeds up to 10 m/s, a resolution of < 1 µm as well as the system precision of < 10 µm speaks for itself. It also features a very good tolerance behavior which facilitates the mounting, adjustment and commissioning.

Reference run no, rugged yes

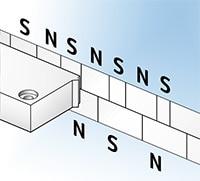

TTK50 magnetic tape with absolute (up) and incremental (bottom) track

TTK50 magnetic tape with absolute (up) and incremental (bottom) track

As absolute measuring linear encoder, the TTK50 does not require a reference run when starting up or restarting a machine. For calculating the absolute position values during the operation, the read head initially detects the absolute starting position when the linear motor starts. The drive controller subsequently calculates the actual position of the drive via of the Sin/Cos signals of the read head. To ensure the reliability of the system, the drive controller can query the absolute position of the read head cyclically and compare this with its calculated actual position. This permits an early detection of any position deviations which can be corrected accordingly.

In comparison to optical linear systems, the TTK50 uses the magnetic principle of operation which offers clear advantages with regard to price, susceptibility to contamination and availability. The rugged metal housing features an IP 65 enclosure rating and two high-torque mounting holes which ensure a secure, vibration- and impact-resistant attachment of the sensor head.

HIPERFACE® and electronic type label

The TTK50, like its big brother the TTK70 also features an electronic type label for automatic controller parameterization. This facilitates commissioning by the user considerably since the drive controller automatically reads out all relevant characteristic data off the drive system from the data fields in the motor feedback system. The transfer of drive and motor characteristics as well as the commissioning information from the drive to the linear encoder occurs via the bidirectional HIPERFACE® interface - likewise in the other direction for the transfer of the position values to the higher-ranking evaluation electronics of the linear drive. The integration of the HIPERFACE DSL® interface, purely digital for the very first time, into the linear encoder is already underway.

Wherever drive solutions need to be extremely precise, fast and dynamic, linear drives are the first choice - and this also includes the TTK50 compact linear motor feedback system.

- Product information: Linear motor feedback system TTK50

- Product portfolio: Motor feedback systems