The maritime energy revolution is officially in swing and has now reached an ambitious level. The sensors from SICK measure the CO2 emissions from combustion processes and are approved for emissions reporting at the EU and international level. There will still be quite a lot more changes onboard in future.

Stage win: pressure leads to action – decarbonization with SICK

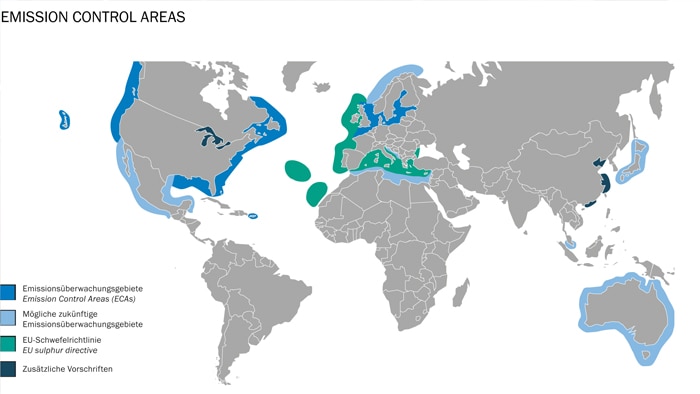

In April 2018, the International Maritime Organization (IMO) approved a strategy for reducing greenhouse gas emissions. The goal is to reach zero CO2 emissions before the end of this century. Whether the decarbonization project is visionary, ambitious or realistic remains to be seen. At least the figures are on the table. 50% of the total CO2 emissions relative to 2008 need to be eliminated by 2050. The milestones have been defined. The average carbon intensity, that is the amount of carbon dioxide emissions per tonne and mile, needs to be cut by 40% before 2030. And the plan is to emit 70% less CO2 by 2050. The industry even aims to exceed these targets. From 2030, large ships will use only climate-neutral fuels. Around one hundred companies from the maritime, energy, infrastructure and finance industries have joined together to form a “Getting to Zero” coalition for this purpose.

Springboard for new possibilities

Course for energy efficiency

Until the new fuels begin to make an impact, transitional solutions are required to increase the energy efficiency. While the command “Full power ahead” will most likely have to give way to lower traveling speeds, it can still provide the motivation for future measures, however. Current mature solutions can lower the emissions per ship by around 20–30%, depending on the type of ship, without having to travel more slowly. A streamlined hull reduces the ship’s drag. Energy efficiency can therefore also impact on ship design, and is therefore prescribed through mandatory rules in the EEDI. Climate protection and energy efficiency will continue to drive technological advances for quite some time.

Signs of a new era

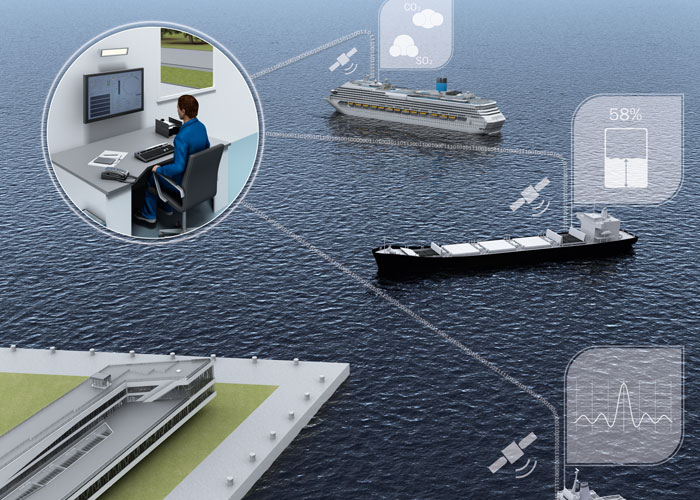

The MARSIC ship emission measuring device measures the CO2 emissions from combustion processes and ship engines and is approved for emissions reporting according to EU regulations (MRV) and international regulations (IMO DCS). The waste gas flow rate is also recorded for reporting purposes. The FLOWSIC100 flowmeter performs its measurements with impressive reliability, regardless of the fuel, the operation of the engines and boiler, or the exhaust gas treatment system used onboard. The FLOWSIC600-XT gas flow meter measures the gas consumption of LNG-powered engines for reporting to authorities. Methane, a gas that is harmful to climate is present as a result of incomplete combustion in LNG engines, is also included in the list of gas components measured by MARSIC. The onboard sensors from SICK send the measured values into the cloud and provide a clear picture of the energy efficiency.

The need to cut CO2 emissions is driving innovations, and this will be the case for some time. Harnessing the power of wind for ship propulsion is increasingly becoming an area of focus. The concept is, after all, not a new one as sailing ships have existed since before written history. From the 9th century onwards, ocean-going ships have sailed long distances over the sea. Now automation is playing an increasingly important role.

The sensors from SICK, with their broad range of applications, are fostering the development of optimized and efficient ship propulsion systems. Today and tomorrow.