ARBURG is a global leader in the manufacture of high-quality injection molding machines. The company was searching for a solution that would identify incorrectly positioned inserts, preventing the production of faulty parts as well as machine downtimes and tool damage for a machine with a vertically arranged clamping and injection unit.

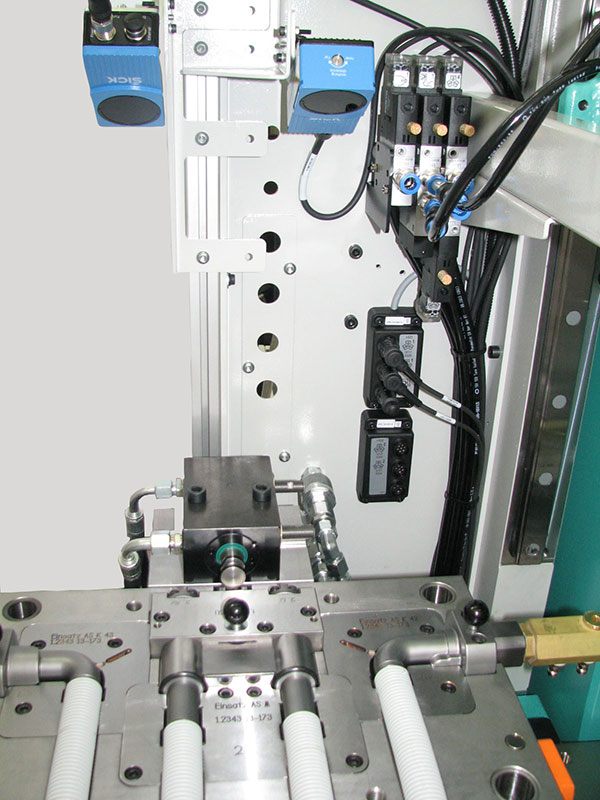

ARBURG installed four Inspector PI50-IRvision sensors above the base of the injection molding tool - two on the right and two on the left at the height of the end positions of the sliding table - in order to determine the position of the inserts (hoses) which are manually positioned in the injection molding tool by the operator. The vision sensors identify incorrectly positioned inserts, preventing the production of faulty parts as well as machine downtimes and tool damage.

The Inspector is not sensitive to ambient light thanks to its infrared lighting. The SOPAS configuration software allows for easy configuration of the sensor. Even without specific vision knowledge, the sensor can be commissioned quickly and easily. The rugged IP67 metal housing is adapted for industrial use. Thanks to its intelligent integrated image processing, the Inspector is perfect for a number of additional quality inspection tasks involving plastics injection molding machines, such as carrying out thorough checks for underfilling, overfilling, or burr formation in the injected plastic parts, as well as monitoring whether the sprue has been correctly removed from the part or whether all plastic parts have been removed from the injection molding tool.

Product family Inspector vision sensor

Product family Inspector vision sensor

Production efficiency increased

ARBURG has now minimized its production of faulty parts, increasing the production efficiency of the overall system, through the use of the Inspector, which is very competitively priced compared to other image processing systems.

Videos: Various fields of applications for Inspector vision sensor

- Product informationen: Inspector PI50-IR

- Product portfolio: vision sensors

- Customer information: ARBURG

ARBURG, based in Loßburg, Germany, is a global industry leader thanks to its electric, hybrid, and hydraulic plastics injection molding machines. The modular product range covers everything from hydraulic starter models and hybrid high-performance machines to high-precision electric and ergonomically vertical machines.In addition to injection molding machines, ARBURG also manufactures robotics systems and material dryers and conveyors. The company also provides its customers with comprehensive advice and complete solutions, starting with tool design and machine layout, all the way through to complete turnkey automated production cells.

ARBURG, based in Loßburg, Germany, is a global industry leader thanks to its electric, hybrid, and hydraulic plastics injection molding machines. The modular product range covers everything from hydraulic starter models and hybrid high-performance machines to high-precision electric and ergonomically vertical machines.In addition to injection molding machines, ARBURG also manufactures robotics systems and material dryers and conveyors. The company also provides its customers with comprehensive advice and complete solutions, starting with tool design and machine layout, all the way through to complete turnkey automated production cells.