A mountain of work! Many industries manage bulk materials non-stop. And often outside in all types of weather. SICK provides intelligent sensor solutions which enable customers to cope with this challenge.

Get an overview from above. The Bulkscan® LMS511 works with this principle. The laser volume flowmeter also detects the loading position and calculates the center of gravity of bulk materials. This is ingenious – smooth material management.

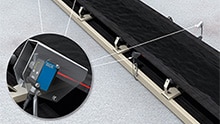

Drift caused by incorrect loading damages the conveyor belt in the long run. The compact Dx35 distance sensor prevents this by monitoring the lateral movements of the belt and sending out alarms automatically. Also works with ambient light and dust.

How fast does the belt really go? Especially when monitoring conveyor belts without a drive, the DFS60 incremental encoder gives reliable feedback about the correct functioning of the conveyor system.

The i110RP rope pull switch is an ideal safety solution for long conveyor systems. It stops the conveyor system if danger exists. The sources of error can be found quickly with signal contacts.