Safe autonomous pallet transportation, maximum space utilization and high process efficiency – the robotics start-up Filics has developed a double skid system for logistics applications that is setting new standards. Crucial to the success of this development is its close collaboration with SICK when using the ultra-compact nanoScan3 safety laser scanner.

Innovation in action: young robotics start-up and experienced sensor technology expert present novel logistics solution

"We have been working long and hard on the load carrier transportation application. While there are vertical solutions available for automated high-bay warehouses that function very well, no automation solution exists for the horizontal transportation all the way into the truck. We would like to change that." Julius Lutzer, COO and co-founder of Filics GmbH, and his start-up team intend to revolutionize ground-based pallet transportation – they are turning bulky, heteronomous industrial trucks into autonomous mobile robots (AMRs).

Maximum space utilization for increased productivity

Pallet handling in the confined spaces in intralogistics continues to be predominantly performed using manual lift trucks and manned forklift trucks. In the view of the start-up company Filics, however, this maneuvering-intensive method of transportation is simply wasteful of space, a scarce and expensive commodity. Efficient space utilization is especially important in traditional block storage systems where pallets are stacked closely together. While conventional transportation methods can only ever pick up and put down the load carrier from one side, the new "Filics Unit" double skid system can successfully pass through and move pallets in or out from the side. This lateral access to the pallets is a decisive advantage because it significantly increases the flexibility and adaptability of the transportation. The Filics Unit can be quickly adapted to different warehouse layouts and transportation requirements, which results in an optimized space utilization and higher process efficiency. A further advantage is the simple feeding of pallets, which keeps the material flow continuous and efficient.

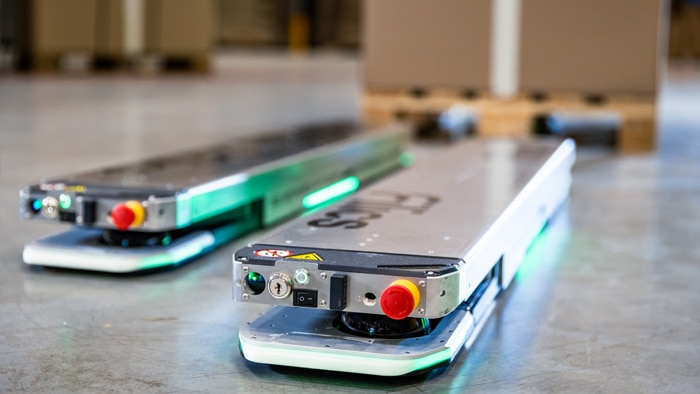

To achieve this, Filics has removed the fork arms from the forklift trucks and manual lift trucks – the remaining skids move autonomously about the warehouse, drive under the pallet stack, dock on there, lift it up, and then maneuver completely freely. Filics calculates that this innovation reduces the costly space requirements in logistics by more than one third. It also brings a whole range of further positive effects as employees can now concentrate on value-adding tasks, and flexibility and productivity increase while overall operating costs fall.

2-in-1 safety solution enables this development

An essential prerequisite for successful automation, however, is ensuring a safe work environment. To this end, the autonomous Filics Unit requires an especially compact, reliable and rugged sensor solution. The ability to pass under the load carriers was made possible by the integration of the ultraflat and compact nanoScan3 safety laser scanner from SICK that ensures the safety of people and materials: "In our 2-in-1 safety solution, two nanoScan3 devices have been installed under the front and rear of the skid respectively in a space-saving manner. With a height of just 80 mm, the smallest safety laser scanner from SICK is especially suitable for simple and space-saving design-in on mobile platforms," explains Klaus Beeker, Key Account Manager Mobile Platforms at SICK.

The precise measurement data of the nanoScan3 ensure the reliable safety and exact localization of vehicles. Decisive for the achievement of adequate speeds are the 128 freely configurable fields that protect the route up to 3 meters ahead and with a scanning angle of 275 degrees. And the more protective fields are available, the more agile the vehicle can move about. To this end, the engineers at Filics configure the necessary protective fields virtually using the free Safety Designer (SD) software from SICK and import them into the laser scanner. This import function of the nanoScan3 makes it possible to provide it with a large number of fields and thereby fine-tune the move in, move through and move out operations.

Filics Unit successfully in use at DHL

For Schmid, SICK is much more than just a hardware supplier: "We really appreciate that SICK, in contrast to many established companies, is not interested only in optimizing its core business in times of crisis like now. To create new things, you need courage and a willingness not only to recognize but also to promote opportunities." Filics intends to work with SICK to continuously further develop and optimize its innovations. In the next step, Filics will be particularly focusing on building up trust with suppliers and customers in a global market as the company wants to grow in order to further advance the automation of logistics processes. One thing is clear to the CCO of the start-up: "With SICK as an innovation partner, we have the greatest possible know-how at our side when it comes to all the challenges in safety solutions."