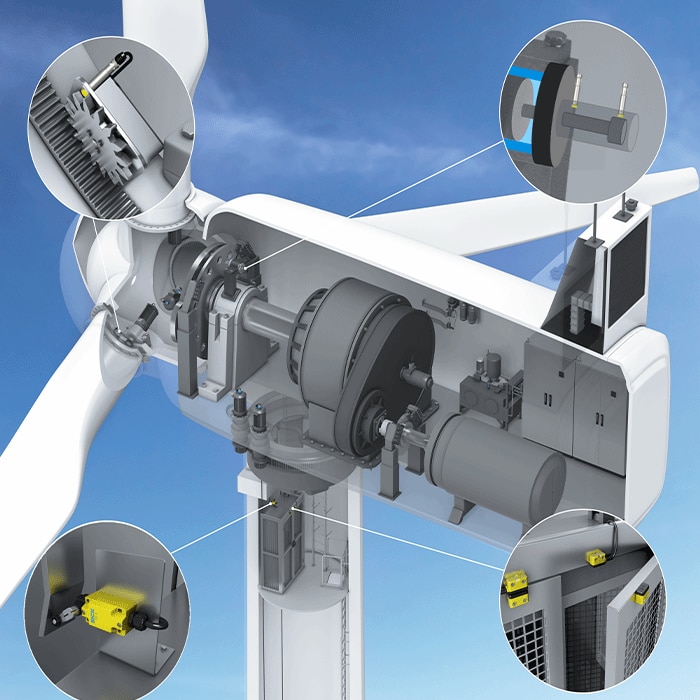

A wind turbine is a machine as defined by the Machinery Directive and must therefore meet legal requirements for the safety of the system. This is especially important because the nacelle and rotors are extremely heavy. People working on these elements for maintenance purposes must be protected against hazards posed by the moving parts. Thanks to its decades of experience in the field of safety, SICK is well prepared for the energy transition and has a broad portfolio of safe sensors for wind turbines. A worldwide network of certified safety experts stands at the ready to carry out risk assessment, planning and inspection for the wind turbine, thereby ensuring legal certainty.

Safety sensors for personal protection at wind power plants

Safe sensors

The main technical difference between a standard sensor and a safety sensor is that a safety sensor has a redundant system. It has two microprocessors that communicate with each other and check each other’s internal and external measured readings from the OSSDs. In the event of an error, the sensor triggers a cut-off at the safety controller and maintains the safety function until the error is rectified.

Safe applications on wind turbines

Safe position monitoring of rotor blades

The goal of wind power plants is to generate the maximum amount of electricity per year with the wind energy available naturally. At the same time, the system’s rotor blades must be protected from overloading in order to prevent damage to the wind turbine and, in particular, personal injury. It is therefore important to constantly and safely monitor the position of the rotor blades, and to adjust the position according to the wind strength. The IME2S inductive safety sensor monitors the safe position of the ring gear on the motor or rotor blades.

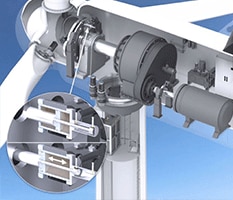

Safe monitoring of rotor lock systems

A wind turbine’s engine room is entered for maintenance or other purposes. When the rotor blades are spinning, this poses a potential hazard to personnel. To prevent the wind power plant from rotating accidentally and injuring people, a safe rotor lock system with a hydraulic or electromechanical locking mechanism is recommended. This is an essential safety component. The double-acting hydraulic cylinder causes the latch to retract and extend, locking the rotor disc. The maintenance-free IME2S inductive safety switches transmit the safe position of the bolt, “rotor disc locked” and “rotor free”, to the control system.

End position monitoring in the elevator shaft

The i110R safety position switch checks that the end position is maintained in a wind turbine’s elevator shaft and prevents overrunning. When an end position is reached, the elevator drive is stopped safely. Thanks to its robust metal housing, the i110R is very well suited for harsh environments.

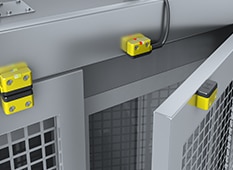

Monitoring and safeguarding safety doors and maintenance flaps

Depending on the risk assessment, door monitoring or door locking may be considered. As an engine room, the access door to the nacelle must usually be secured to protect people from injury. The RFID-monitored safety locking device flexLock is mounted on the door, ensuring that the door can´t be opened until the wind turbine is in a safe condition. This means that the rotors are safely stopped, or only run at a safely reduced speed.

An STR1 RFID safety switch is also attached to maintenance flaps or doors. This monitors whether the maintenance flap is open or closed and initiates an appropriate safety response. In addition, personnel always receive a status overview of whether the flap has been closed again.

Safety to performance: Safety devices from a single source

To operate the wind turbine safely, process conditions and parameters must be clearly defined. Depending on the risk assessment of the plant, different safety switches are used, which are connected to the standard control system via a safety controller. Status and diagnostic functions can be read out easily and ensure smooth processes.

Thanks to its modular hardware platform, the Flexi Compact safety controller can be configured for a wide variety of control scenarios. The license-free Safety Designer enables intuitive configuration, fast commissioning and continuous diagnostics.

Everything from a single source: from best-in-class products and safety systems to complete projects. SICK offers support on the way to safe operation of wind power plants and has safety expertise for a safe application solution.