SICK's reliable and user-friendly W11-2 and W4-3 photoelectric sensors help Swiss trading company Avesco AG to provide a fast delivery service for construction machinery components.

SICK's photoelectric sensors ensure that the right parts end up in the right place in Avesco AG's warehouses.

Head of Logistics at Avesco AG

Head of Logistics at Avesco AG

"With the aim of offering customers an even better delivery service, we have contracted system supplier Gilgen Logistics AG to modernize the spare parts warehouse and integrate a new small parts warehouse with 14,400 storage bays on 15 levels," explains Mirko Scheidegger, Head of Logistics at Avesco AG. In most cases, an order placed in the evening can now reach the customer the next morning. "Orders can be picked from up to 400 totes per hour, around the clock," adds Roman Bolliger, Deputy Head of Logistics. Delivery at such speed is made possible by highly optimized material flow processes in the warehouse, where SICK photoelectric sensors play an important role.

WL11-2: reliable detection on the pallet lift

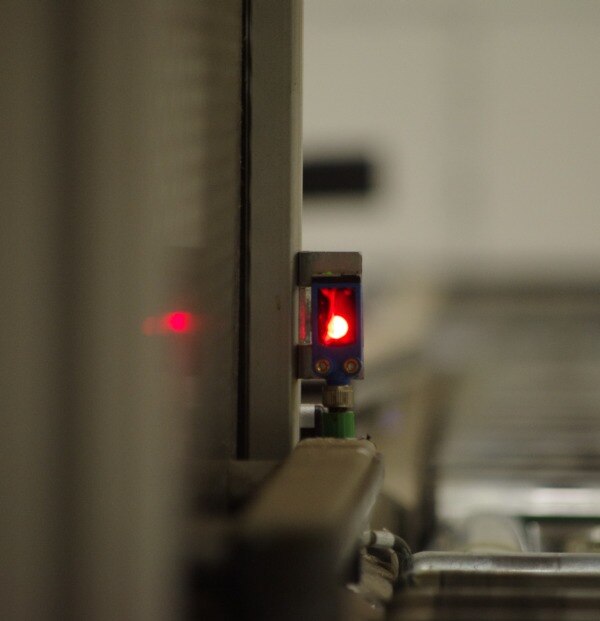

WL11-2 small photoelectric sensor

WL11-2 small photoelectric sensor

Avesco's construction machinery warehouse includes a high-performance pallet conveyor. The WL11-2 small photoelectric sensors can be relied upon to detect pallets entering and leaving a pallet lift and stop pallets in the correct location. The WL11-2 photoelectric sensor with PinPoint LED is able to detect any type of pallet with precision between 0.1 and 5 m, regardless of surface brightness or possible film wrapping. "This means that the sensors are able to achieve maximum reliability where detection and output are concerned," attests Roman Bolliger. In addition, commissioning is easy, quick, and does not require specialist knowledge.

W4-3: space-saving and powerful in the tote warehouse

WL4-3 photoelectric retro-reflective sensor

WL4-3 photoelectric retro-reflective sensor

The new small parts warehouse has to meet a variety of challenges. First, most Avesco customers cannot afford to wait long for spare parts - things have to move quickly. Second, space is at a premium in the warehouse. Compact sensors were essential. The W4-3 miniature photoelectric sensors fit the bill in every way: Numerous WL4-3 photoelectric retro-reflective sensors and WTB4-3 photoelectric proximity sensors can be relied upon to detect the compact spare parts crates on the package conveyor in the highly frequented spare parts warehouse. Despite being no larger than a sugar cube, the photoelectric sensor is extremely rugged and can be used in even the most confined spaces. Thanks to their compact size, extreme ruggedness, and quick and easy commissioning, they are ideally suited to integration in a restricted package conveyor. "Despite their small dimensions, there is no compromise on performance as far as they are concerned," confirms Mirko Scheidegger.

Praise for service from SICK and user-friendly sensors

Throughout the Avesco project, SICK impressed by providing expert advice and flexibly applying customer-specific requests, such as when it came to standardizing connectors. SICK's sensors also received praise from those responsible for the project: "They are rugged, reliable, user friendly and low maintenance," says Mirko Scheidegger. "Our team has encountered no problems whatsoever." This was confirmed by his colleague Roman Bolliger: "As a plant operator, it's a simple task for us to replace and correctly configure the sensors in an emergency."

- Infomation Avesco AG: Based in Langenthal, Switzerland, Avesco AG distributes trade products in the construction machinery, structural engineering, plant engineering, and material handling and energy systems sectors. Its suppliers include, for example, the construction machinery manufacturer CAT, the Sandvik engineering group, and Yale in the materials handling sector.

- Product informationen : W4-3 miniature photoelectric sensor, W11-2 small photoelectric sensor, WTB4-3 photoelectric proximity sensor

- Product portfolio: Miniature photoelectric sensors, small photoelectric sensors

- Customer information: Avesco AG, Gilgen Logistics AG