Increasingly stringent laws and regulations on emissions monitoring pose a challenge for shipyards. Digital solutions can help – like SICK’s MARpems: the system delivers valid emissions data, even when monitoring systems break down. The SICK Maritime Suite, the digital solution for the maritime industry, has now been expanded with a further intelligent component: MARpems, which stands for Maritime Predictive Emission Monitoring System, guarantees the availability of emissions values on board ships – even when the data from their continuous emission monitoring systems is interrupted.

Digital twin on board: Predictive Emission Monitoring on ships

It can do so thanks to an algorithm that, in the event of an interruption, calculates certain key parameters on the basis of the remaining exhaust gas data, ensuring seamless compliance for ship operators. “MARpems is the result of a start-up initiative launched by SICK in 2018,” says Fabienne Jäckle, Product Manager Cleaner Industries. “As there was already this type of solution for land-based applications, we recognized an attractive business case in the maritime sector and developed an initial corresponding product.”

Results were soon available, and even in this comparatively early phase of product development, SICK got the classification society DNV on board, to ensure that the solution would also be officially recognized. A clever move: the data model underlying MARpems was assessed by DNV Service in Høvik, which issued a “Statement of Product Capability” for it. In turn, DNV Maritime in Hamburg provided a technical evaluation of MARpems’s functionality for scrubber applications and confirmed its suitability to the German flag.

Continuous monitoring of emissions values

In the summer of 2023, it was time for MARpems’s premiere: in Long Beach, California, the solution was first installed on a container ship from the CPO shipyards. CPO has been working with SICK to develop digital solutions for the maritime sector since 2020. Since the installlation, CPO has had access to the entire SICK Maritime Suite and its various functions, which offer comprehensive information on emissions, the performance of the exhaust gas treatment system, the status of the emissions monitoring equipment, etc.

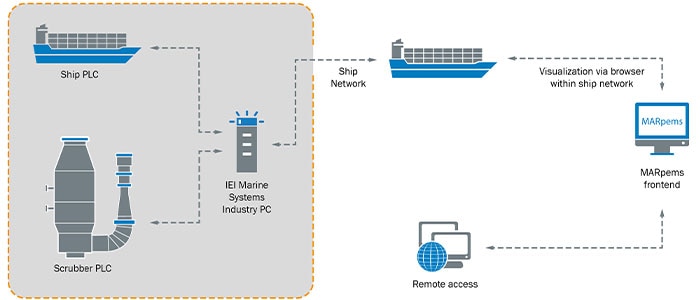

More concretely, the new digital service MARpems works as follows: ships that run on marine fuel oil have onboard exhaust-gas treatment systems, called scrubbers, which reduce sulfur emissions. Continuous Emission Monitoring Systems (CEMSs) – like the MARSIC analyzers from SICK – check the scrubbers’ efficiency by measuring the sulfur dioxide and carbon dioxide concentration in the treated exhaust. Ship operators are required to constantly monitor these emissions values, record them, and report them to the authorities as needed. When a CEMS breaks down, certain exhaust gas values become unavailable, and the ship operator can no longer prove their ship’s compliance with the maximum values. Normally, faulty sensors can only be replaced by trained technicians. This poses unforeseekable risks for ship operators, such as additional manual labor, higher costs due to more expensive fuel, or even financial penalties for failure to comply.

Digital twin on board

But MARpems offers out a way: “Essentially, we’re talking about using a digital twin of the faulty CEMS,” says Jäckle. “If a CEMS malfunctions or breaks down, the software automatically kicks in: machine learning models use the available operating data from the ship and scrubbers to calculate the electrical current emissions. In this way, MARpems ensures temporary emissions conformity and therefore compliance with IMO regulations. Although generally the same machine learning models are used, they are individually trained for the respective ship using its specific data from the past several months.

Authorization by flag states

In addition to ensuring compliance while also reducing the time and effort when a CEMS breaks down, MARpems has another positive effect: the solution increases transparency on the status of the emissions monitoring equipment and scrubbers, which can help to avoid or plan short-term repairs and maintenance. Accordingly, the system boosts process reliability and reduces service calls to a minimum. All in all, MARpems increases operating efficiency and competitiveness. Today, MARpems is officially recognized by the flag states Germany, Malta, and Liberia. Flag states define supervisory regulations concerning technical and administrative matters on board the ships flying their flag. The approval of further flag states is expected in the near future: “We’re already in talks with the maritime organizations of further countries,” says Fabienne Jäckle. “In this way, we’re actively expanding the acceptance of our solution, step by step.”