Latexco is one of the worlds leading manufacturers of latex components for the bedding industry. The various sizes of latex mattresses, pillows, and mattress toppers made on its three production lines require a high-performance logistics center. A network of 25 bar code scanners from SICK steers the individual mattress components, ensuring that orders are always fulfilled with the right types and quantities.

Its latex mattresses, pillows, and mattress toppers (latex overlays for existing mattresses) are known for their high quality. They ensure a high degree of comfort during sleep because the manufacturing process enables the combination of hardness and density to be fine-tuned to specific needs.

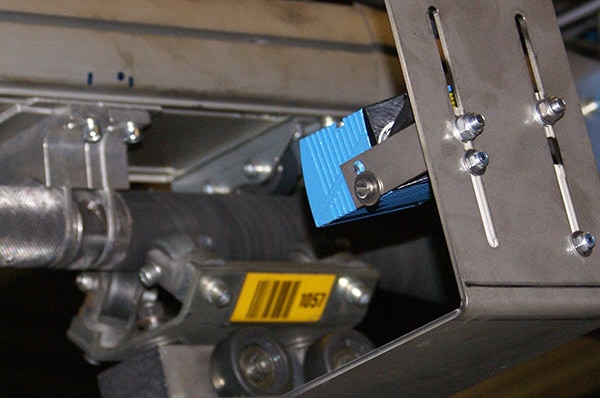

Once they have passed through large molds, ovens, and quality controls, the finished mattress cores are given a label and a bar code. At the end of the production line, they are mounted on a trolley: a type of frame that hangs on an overhead conveyor system. Each trolley has its own distinctive bar code, and as soon as the mattress is clamped into a trolley, CLV610 bar code scanners read both bar codes. This allows the system to link the mattress data with that of the trolley. The trolleys then transport the mattresses to a logistics center, where they are sorted one by one with the aid of an overhead conveyor system, which is arranged into five large carousels.

Because the mattresses are made on three production lines and must then undergo quality control and possibly some post-processing, they arrive at the logistics center in a random order. Once a trolley has been loaded with a mattress and is hanging on the belt, both items are scanned. The decision as to which carousel the trolley will travel to is made based on the mattress type. The system leaves the trolleys revolving on the carousel until the new mattress can be sorted with previous items of the same type. If there are no other mattresses of this type, the mattress is inserted into a gap in the carousel as a new type, so that mattresses of the same variety can be added later. These processes are fully automated, as is the process of removing mattresses, which is initiated as soon as a mattress type reaches the number required for palletizing.

All activities in this sorting system are controlled based on the data recorded when the trolley bar codes are scanned. Using these codes, the PLC knows which mattresses have arrived at the carousel, which mattress types are currently on the carousel, and which products have left the conveyor system. The CLV610 bar code scanner is the perfect solution for this application. Latexco has been using SICK bar code scanners for several years. Since this technology fulfilled expectations to the clients complete satisfaction (after more than 15 years, the scanners still perform to the same standard as they did on their first day in service), they decided to continue using SICK products when modernizing their bar code scanner system last summer. The high degree of reliability offered by the new scanners and the sophisticated sorting process guarantee that every mattress will reach the correct destination - and everyone can sleep easy.

Latexco video

- Product informationen: CLV61x bar code scanner

- Product portfolio: Bar code scanner

- Customer information: Latexco