Counting impulses and detecting changes in speed one step earlier based on acceleration - this combination unprecedented on the market is provided by the SAM inductive proximity sensor from SICK.

Now process-critical conditions, such as slip, belt breakage, breaking, and overload can be detected far more quickly using the SAM. This serves as an efficient way to prevent damage to machines or rejects.

Speed monitoring redefined

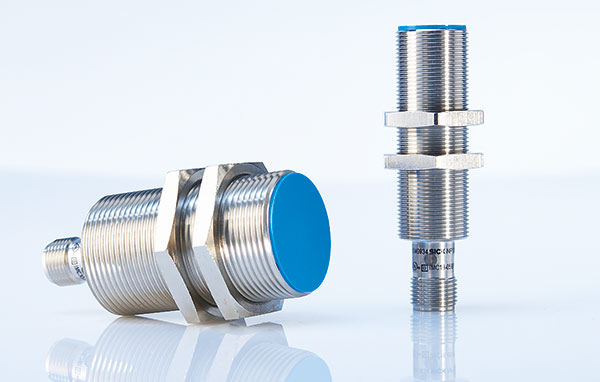

A world first, the sensors of the SAM product family in the cylindrical M18 or M30 metal housing, respectively, can be used for the first time optionally as classical impulse monitors or as innovative acceleration monitors. Designed for speeds of 6 to 12,000 impulses a minute - twice as many as in the case of conventional devices - they monitor even fast processes efficiently and cost-effectively. It is possible to monitor acceleration within a range limit of 0.1 to 2 impulses per second² with an impulse train up to a maximum of 1,200 impulses per minute. There is the option of using the SAM sensors either as switching stand-alone devices or, integrated into an IO-Link environment, they are able to output current measuring data. Configuration occurs accurately and easily using a PC.

Valuable seconds: Malfunction indication without Δt

Whereas in the case of pure impulse monitoring a period of time will pass until the machine shaft reaches a defined limit value when deviating from its set speed, acceleration monitoring does not have this Delta T (Δt). Since at constant speed, the positive or negative acceleration, respectively, is zero, any change in speed is not detected only by the time a limit value is reached but immediately in case of any acceleration or delay, respectively, that is unequal to zero. The seconds saved in this way are often valuable since they make it possible to immediately signal malfunctions such as slip or overload of the drive train, the tearing of web, sheet, or film material, or the breaking of a drive shaft, etc. Frequently, both damage to machinery and production rejects are reduced considerably in this way.

Speed measurement with SAM in a packaging machine

More flexibility: monitoring independent of speed

Thanks to the new acceleration monitoring of the SAM sensors, changes of format and speed are a breeze. Since SAM sensors monitor only changes in the process but not the absolute speed of the impulse train, it is not necessary to readjust the limit values when speeds change. Apart from the savings in time and costs, this also constitutes a definite gain in flexibility.

Intelligent in its simplicity: start-up override

The intelligent start-up override adjusts automatically to the start-up time required by the machine. This method not only facilitates commissioning but also compensates automatically for unexpected changes of the machines start-up time. Simple, flexible, fast, and reliable - the first integrated impulse and acceleration monitor SAM stands for the new, intelligent approach in speed monitoring.

- Product information: SAM inductive proximity sensor

- Product portfolio: Proximity sensors, inductive proximity sensors