1946

The company known today as SICK AG is born:

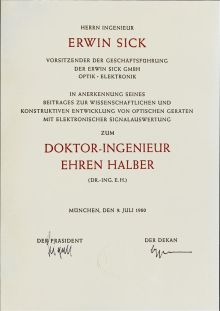

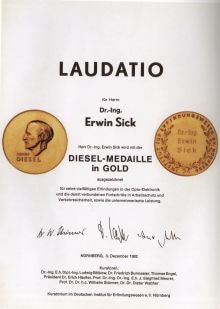

Erwin Sick obtains a license from the American military government in Munich to set up his own engineering firm.

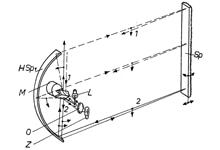

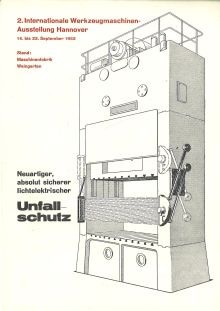

1952

Presentation of the first marketable accident prevention light curtain at the International Machine Tool Trade Fair in Hanover. The orders that followed led to the initial serial production and the economic breakthrough.

1956

The company moves to Waldkirch, Germany with its 25 employees.

1972

The first subsidiary is founded in France.

1975

The company expands overseas with the founding of a subsidiary in the USA.

1988

Erwin Sick dies at the age of 79. Gisela Sick takes over from her husband and leads the company as its primary shareholder.

1996

Erwin Sick GmbH changes its company status to an “Aktiengesellschaft” or joint stock company.

1999

The first employee shares are issued domestically and abroad.

2006

SICK celebrates its 60th anniversary.

2023

SICK is one of the world’s leading solutions providers for sensor-based applications in the industrial sector. Founded in 1946 by Dr.-Ing. e. h. Erwin Sick, the company with headquarters in Waldkirch im Breisgau near Freiburg ranks among the technological market leaders. With 60 subsidiaries and equity investments as well as numerous agencies, SICK maintains a presence around the globe. SICK has more than 12,000 employees worldwide and generated a group revenue of EUR 2.3 billion in the 2023 fiscal year.